- Don’t Risk Your Brand: The Guide to 5 Red Flags When Sourcing Apparel Manufacturers

- The New Reality: How COVID-19 Changed Sourcing Priorities

- What is a “Red Flag”? A Simple Guide for B2B Buyers when they want to know “Red Flags When Sourcing Apparel Manufacturers”

- Key Concern 1: Solving the Mystery of Unusually Low Quotes

- Key Concern 2: Ensuring Bulk Quality Matches the Approved Sample

- Key Concern 3: Seeing Through Deceptive and Unrealistic Promises

- Key Concern 4: A Manufacturer’s Response to Their Own Mistakes

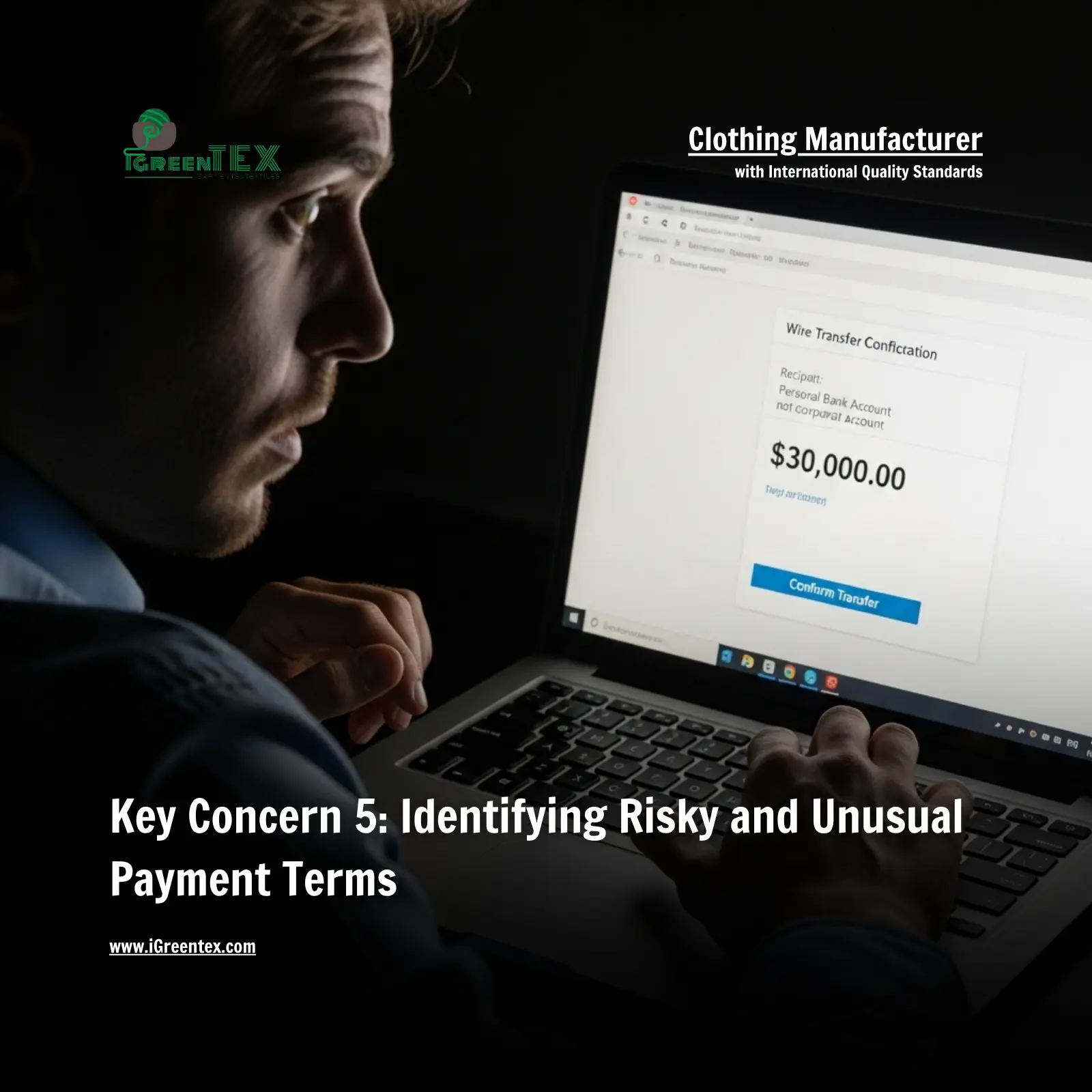

- Key Concern 5: Identifying Risky and Unusual Payment Terms

- Beyond the Basics: Advanced Checks to Secure Your Supply Chain

- iGreen Tex Vietnam: Your Reliable OEM Manufacturing Partner

- About iGreen Tex Vietnam

- IGREEN TEX VIETNAM CO LTD

Don’t Risk Your Brand: The Guide to 5 Red Flags When Sourcing Apparel Manufacturers

Choosing a manufacturing partner is a critical decision for your apparel brand. A reliable partner ensures quality and supports your growth. A bad partner can cause huge financial losses and damage your reputation. This can lead to lost seasons and angry customers. This guide will help you tell the difference between them. We will focus on the most important red flags when sourcing apparel manufacturers. Learning these warning signs will protect your business. It allows you to build a secure and dependable supply chain. This is your essential checklist for success.

This guide provides simple, actionable steps for B2B buyers. We will explain how to identify potential problems early. Knowing the common red flags when sourcing apparel manufacturers empowers you to ask better questions. You can evaluate suppliers with much more confidence. Our main goal is to help you avoid costly mistakes. For any business looking for a great clothing factory, understanding these red flags when sourcing apparel manufacturers is the most important first step. This knowledge is crucial for making safe and smart sourcing decisions for your brand’s future.

The New Reality: How COVID-19 Changed Sourcing Priorities

The global pandemic fundamentally changed the manufacturing landscape. Supply chain disruptions exposed major weaknesses worldwide. For B2B buyers, this created a significant shift in thinking. Before, the lowest price was often the top priority. Today, reliability and transparency are far more important. Businesses learned that a cheap supplier who cannot deliver product is incredibly expensive. This new awareness has made it even more critical to identify red flags when sourcing apparel manufacturers. Buyers are now more cautious and risk-averse than ever before.

This new mindset directly impacts how you should evaluate partners. The pandemic showed that empty store shelves lead to lost sales. Buyers are moving away from risk and toward security. They need to know a factory can handle unexpected challenges. They need proof of a stable operation. This means looking deeper than just the price tag. A strong partnership is about resilience. It is about clear communication during a crisis. Therefore, the ability to spot red flags when sourcing apparel manufacturers is no longer just good practice. It is an essential survival skill for modern apparel brands. Your brand’s stability depends on it.

What is a “Red Flag”? A Simple Guide for B2B Buyers when they want to know “Red Flags When Sourcing Apparel Manufacturers”

Let’s define what a “red flag” actually means in a business context. A red flag is not absolute proof that a manufacturer is bad. It is a warning sign. It is an indicator that you must investigate a specific issue more deeply. When you see a red flag, it is time to pause and ask more questions. Think of it as a stop sign on the road. You must stop, look, and listen before proceeding. Ignoring these signs is a major business risk. These warnings are the most important red flags when sourcing apparel manufacturers. They are signals that require your immediate attention for due diligence.

For a B2B buyer, each red flag points to a potential business problem. If a price quote is extremely low, the red flag is a warning about potential hidden costs. If a supplier is slow to respond, the red flag warns of communication problems during production. These are not small issues. They can affect your budget, your product quality, and your launch dates. Learning to identify these red flags when sourcing apparel manufacturers is a proactive strategy. It helps you objectively compare different suppliers. It is about protecting your business from predictable failures and building a more secure supply chain.

Key Concern 1: Solving the Mystery of Unusually Low Quotes

Your first pain point is often an attractive price. A manufacturer offers a quote that is much lower than all others. This is one of the most tempting red flags when sourcing apparel manufacturers. Your immediate thought is about saving money. But your real question should be: “What costs are they not showing me?” An abnormally low price is almost always a sign that something is missing. Dishonest suppliers use this tactic to win your business first. They add more charges later, once you are already committed. This is a classic bait-and-switch tactic.

To solve this, you must investigate the hidden costs in apparel manufacturing quotes. A professional manufacturer will provide a clear, itemized price list. An unreliable one will not. You must ask direct questions. Does the price include custom labels and hangtags? Does it include inner poly bags and master shipping cartons? Are there extra fees for creating lab dips for color matching? What about customs brokerage fees at the port? These small items add up. They can turn a cheap quote into a very expensive final cost. A refusal to provide this detail is one of the clearest red flags when sourcing apparel manufacturers.

What a Transparent Quote Should Include

A trustworthy manufacturer will not hide information. Their quote will be a detailed document. It should clearly list the price per unit. It should specify the fabric type and weight. It must also list all included services. This includes things like the cost of creating a pre-production sample. It should detail all packaging components. A good quote also clearly states the shipping terms (like FOB – Free On Board). This transparency is the opposite of the financial red flags when sourcing apparel manufacturers. Demand this level of detail. A professional partner will gladly provide it to build your trust.

Key Concern 2: Ensuring Bulk Quality Matches the Approved Sample

A major fear for brands is poor quality in the final production. You approve a perfect sample, but the bulk order is completely different. This is a common and costly problem. It is also one of the most serious red flags when sourcing apparel manufacturers. This issue often happens when a factory uses its best resources only for samples. They do not apply the same quality standard to the main production line. This inconsistency signals a very weak or non-existent quality control system. It is a risk you cannot afford to take with your brand’s reputation.

You can identify apparel sample development problems early. First, look at the sample cost and timeline. A factory that charges extremely high fees for samples may not be serious about production. Second, constant delays in getting samples show poor organization. These are significant red flags when sourcing apparel manufacturers. Furthermore, the sample must match your technical packet exactly. If the factory ignores your specifications, it shows a lack of attention to detail. Watch how they handle your feedback. Do they implement changes correctly on the next version? Or do they argue and make excuses? A difficult sample process almost always leads to a difficult production process.

The Importance of the “Golden Sample”

To protect yourself, always ask for a “golden sample” or “sealed sample.” This is the final, perfect pre-production sample that you approve. Both you and the manufacturer should keep an identical, sealed copy. This sample becomes the official quality standard for the entire bulk order. Your contract should state that the bulk production must match this golden sample. A factory that resists this simple, professional step is showing one of the major red flags when sourcing apparel manufacturers. It suggests they are not confident in their ability to maintain quality.

Key Concern 3: Seeing Through Deceptive and Unrealistic Promises

When you speak to new suppliers, you will hear many attractive claims. Your challenge is to know which ones are real. Believing false claims is a critical error. Some of the most dangerous red flags when sourcing apparel manufacturersare found in these promises. Inexperienced or dishonest factories will say anything to get your contract. These claims sound good but often lead to failure. You must be able to identify these empty promises to protect your brand from disappointment.

Here are specific unrealistic promises from clothing manufacturers to watch for. Be cautious if a factory says, “We can make any type of product.” True expertise often comes from specialization. A factory that claims to be an expert in everything is often an expert in nothing. Another major red flag is the promise of being the “cheapest.” The lowest price always comes at a cost. That cost is usually quality, ethical standards, or reliability. Finally, beware of promises for “extremely fast” production. Quality work takes time. A rush job means cut corners. These are all clear red flags when sourcing apparel manufacturers. Also be wary of claims like “We work with famous brands” if they cannot provide proof.

Key Concern 4: A Manufacturer’s Response to Their Own Mistakes

Even in good factories, production mistakes can happen. The true test of a partner is not if they make mistakes. It is how they react when they do. A poor response is one of the most telling red flags when sourcing apparel manufacturers. Experienced buyers know this. They are less concerned with the mistake itself and more concerned with the factory’s solution. An unreliable partner will try to hide the problem. They might ship the defective goods, hoping you will not notice. This behavior is unacceptable and can destroy your business.

You need to know how manufacturers handle production mistakes. A bad partner becomes defensive. They will blame your technical packet or the fabric. They will refuse to accept responsibility. This is a massive red flag. It shows a complete lack of integrity. A good manufacturer, however, follows a clear process. First, they inform you immediately. Second, they investigate the root cause of the problem. Third, they propose a fair solution. This could be remaking the items, reworking them, or offering a discount. This honesty is a sign of a true partner. This is why avoiding these red flags when sourcing apparel manufacturers is so important.

Key Concern 5: Identifying Risky and Unusual Payment Terms

Financial transactions are a point of high risk. The payment terms a factory requests can tell you a lot about their stability. Unprofessional or insecure payment demands are serious red flags when sourcing apparel manufacturers. You must protect your company’s capital. Only work with partners who use standard, safe payment procedures. A supplier’s approach to finance is a direct reflection of their professionalism. Any strange financial request should be a major cause for concern.

One of the most unusual payment terms from garment suppliers is a request for a huge deposit. The industry standard is typically 30% to 50% upfront to buy materials. A factory demanding 70% or more before starting work is a major risk. It could mean they have financial problems. They might be using your money to pay other debts. This is one of the most critical red flags when sourcing apparel manufacturers. Also, always check where the money is going. Payments should go to a corporate bank account, never a personal one. A sudden request to change bank account details is also a major red flag for fraud.

Beyond the Basics: Advanced Checks to Secure Your Supply Chain

Spotting the basic red flags when sourcing apparel manufacturers is a great start. But serious brands must go deeper. Your due diligence should include checks on financial stability and legal protection. This is how you truly protect your brand in the long term. These advanced steps separate professional sourcing from amateur guesswork. They help you build a truly resilient supply chain. These are the checks that experienced industry veterans always perform before placing a large order.

Advanced Check 1: Financial and Legal Verification

Ask for the factory’s business registration documents. Confirm they are a legally registered entity. A factory with nothing to hide will provide this. This check helps you avoid scams. A factory with cash flow problems might cut corners on your order to save money. This is one of the most important advanced red flags when sourcing apparel manufacturers. You want a partner who is financially healthy and can weather economic changes without affecting your production.

Advanced Check 2: The Importance of a Strong Contract

Do not rely on simple emails or purchase orders for a production run. You need a detailed manufacturing agreement. This contract is your most important legal protection. It should clearly define quality standards, delivery deadlines, and penalties for failure. It must include clauses to protect your intellectual property (your designs). A manufacturer who resists signing a fair, detailed contract is showing one of the biggest red flags when sourcing apparel manufacturers. It means they want to avoid being held accountable.

Advanced Check 3: Verifying Compliance and Ethical Claims

Many factories claim to be socially and environmentally compliant. Do not just accept their word for it. This is a common area for deception. Ask to see their full, unedited audit reports from third parties like WRAP or BSCI. A certificate is easy to fake; a full report is not. Also ask about their policy on subcontracting. Unauthorized subcontracting is a huge risk. It means you lose control over quality and ethical standards. A lack of transparency here is another serious red flag.

iGreen Tex Vietnam: Your Reliable OEM Manufacturing Partner

Navigating the world of apparel production requires a partner you can trust. The best strategy is to choose a partner built on transparency. At iGreen Tex Vietnam, our entire operation is designed to eliminate the red flags when sourcing apparel manufacturers. We are a specialized B2B export manufacturer in Vietnam. We provide high-quality OEM services for international brands. Our product focus includes t-shirts, polos, hoodies, and basic sportswear, all made to global standards. We are an OEM-only producer, focusing entirely on bringing your designs to life with precision.

We address your biggest concerns directly. We provide fully itemized quotes so there are no hidden costs. Our expert technical team ensures that the quality of your bulk order perfectly matches the sample you approve. We make realistic promises and maintain clear, honest communication. We welcome detailed manufacturing agreements and operate with secure, standard payment terms. Our process is built to avoid the common red flags when sourcing apparel manufacturers. Accountability is central to our work. If an issue ever arises, we take responsibility and fix it. With iGreen Tex, you avoid the risks and gain a dedicated OEM partner committed to your brand’s success.

In conclusion, careful evaluation is your most powerful tool. You must be diligent when selecting a manufacturing partner. This guide has provided a detailed checklist of the critical red flags when sourcing apparel manufacturers. We have covered everything from misleading prices to unprofessional payment demands. We discussed problems with samples and how to handle production mistakes. Recognizing these warning signs is the best way to protect your brand. It helps you avoid financial loss and protect your reputation. A cheap initial offer can easily become your most expensive mistake.

You must invest time in proper research. Ask specific questions. Demand clear, honest, and complete answers. A professional partner will always respect your diligence. A bad partner will try to avoid it. This diligence is not a cost; it is an investment in your brand’s future. By using this knowledge of red flags when sourcing apparel manufacturers, you can effectively remove unsuitable suppliers from your list. This allows you to focus on building a strong, long-term partnership with a factory that shares your values of quality and integrity. This is the only way to build a resilient and successful global apparel brand.

About iGreen Tex Vietnam

iGreen Tex Vietnam is a trusted fashion and textile manufacturer based in Vietnam, specializing in high-quality sportswear and casual apparel for global markets. We provide OEM manufacturing services, supporting brands to design, develop, and produce customized garments that meet international quality standards.

Our production focuses on sustainability and eco-friendly practices, using certified fabrics and advanced techniques to reduce environmental impact. From material sourcing to final inspection, every stage of manufacturing follows strict quality control processes to ensure flawless results. With years of experience in Vietnam sportswear manufacturing, we understand the demands of global clients and changing fashion trends.

Our factory operates with modern equipment and a dedicated team to deliver products on time and at competitive pricing. Partnering with iGreen Tex means working with a reliable supplier who combines innovation, quality, and responsibility. We help your brand scale effectively by producing garments that resonate with today’s conscious consumers worldwide.

If you want to read more information about canvas bags, and if you want to tote bags at Ho Chi Minh City, you can see it here!!!

To view product information click here

Visit our website to learn more about our products and services: IGREEN TEX

IGREEN TEX VIETNAM CO LTD

Address: No. 6 – 6A, D52 Street, Bay Hien Ward, Ho Chi Minh City, Vietnam

E-mail: Info@iGreentex.com

WhatsApp/Viber/Zalo: +84 (0) 938.045.900