- FINDING SMALL BATCH CLOTHING MANUFACTURERS IN VIETNAM: SOLUTIONS FOR STARTUPS & LOW MOQ ORDERS

- WHAT IS “SMALL BATCH” MANUFACTURING IN VIETNAM?

- CMT VS. PRIVATE LABEL: CHOOSING THE RIGHT MODEL

- THE CHALLENGE: WHY DO FACTORIES REJECT LOW MOQ ORDERS?

- SOLUTIONS FOR STARTUPS: HOW TO NAVIGATE LOW MOQ

- PRIVATE LABEL SERVICES: BUILDING YOUR BRAND IDENTITY

- THE PRICING REALITY: UNIT COST VS. INVENTORY RISK

- IGREEN TEX’S APPROACH TO SMALL BATCH PRODUCTION

- NEW SECTION: LOGISTICS FOR SMALL BATCHES (AIR VS. SEA)

- CASE STUDY: FROM 200 TO 5,000 PIECES

- CONCLUSION

FINDING SMALL BATCH CLOTHING MANUFACTURERS IN VIETNAM: SOLUTIONS FOR STARTUPS & LOW MOQ ORDERS

You have a crystal-clear business concept. Your mood boards are finalized, and your designs are ready for production. You might even have a growing community on TikTok or Instagram waiting for your first product drop. You feel ready.

You spend weeks scouring the internet, filtering through B2B marketplaces, and finally, you find a factory that looks perfect. You send an email full of excitement, attaching your sketches.

Then, 24 hours later, the reply comes:

“Sorry, we cannot accept this order. Our Minimum Order Quantity (MOQ) is 1,000 pieces per style/color.”

This is the dreaded “MOQ Wall.” It is the single biggest barrier to entry for new fashion brands. If you are a founder with a limited budget, hearing this rejection repeatedly is not just discouraging—it is paralyzing. You do not want to order 1,000 t-shirts and risk having them sit in your garage or warehouse forever. You want to test the market, validate your concept, and scale up incrementally.

Here is the good news: The manufacturing landscape is shifting.

While Vietnam is globally renowned for massive industrial production for giants like Nike, Adidas, or Uniqlo, a new wave of flexible manufacturing is rising. Finding reliable small batch clothing manufacturers in Vietnam is completely possible in 2026 if you know where to look, how to speak the industry language, and how to negotiate effectively.

If you are completely new to the industry, we recommend you first read our pillar guide on [How to Source Garment Suppliers in Vietnam] to understand the big picture of the national supply chain.

However, if you are specifically looking to produce smaller quantities (from 50 to 500 pieces) and build a brand from scratch, this “Deep Dive” guide is written exactly for you.

We will analyze why MOQs exist, the detailed economics behind them that most factories won’t tell you, and how iGreen Tex helps startups succeed by acting as one of the premier small batch clothing manufacturers in Vietnam.

WHAT IS “SMALL BATCH” MANUFACTURING IN VIETNAM?

Before we analyze strategies, we must define our terms clearly. “Small” is a highly relative concept in the global supply chain.

In the world of bespoke tailoring, Etsy sellers, or local seamstresses, “small batch” might mean 10 or 20 units sewn by a single person. But when we talk about industrial manufacturing in Vietnam—factories that use professional assembly lines, standardized sizing, and export-quality fabrics—the numbers are different.

To a factory manager in Ho Chi Minh City, an order of 300 pieces is “tiny,” whereas to a startup founder, it feels huge. Bridging this gap in expectation is the first step to finding small batch clothing manufacturers in Vietnam.

TABLE 1: QUANTITY DEFINITIONS IN VIETNAM

| Factory Type | Average Order Size | Typical MOQ | Production Method |

| Export Factory (Tier 1) | 10,000+ pieces | 3,000 – 5,000 pieces | Full Automation Line |

| Mid-Sized Factory | 2,000 – 10,000 pieces | 1,000 pieces | Standard Assembly Line |

| Small Batch Manufacturer | 100 – 500 pieces | 50 – 300 pieces | Flexible Cell System |

| Sample Room | 1 – 50 pieces | 1 – 10 pieces | Single Operator |

TABLE 2: ORDER TYPES FOR SMALL BATCH PRODUCTION

| Order Type | Quantity Range | Primary Purpose |

| Sample Order | 1 – 5 pieces | Prototyping, fitting, and photography. |

| Pilot Run (MVP) | 100 – 300 pieces | Market testing (usually split into 2-3 colors). |

| Growth Run | 500 – 1,000 pieces | First commercial launch for verified products. |

Understanding where you fit in this table helps you target the right partners. iGreen Tex positions itself in that specialized “Small Batch Manufacturer” tier, designed specifically to support growth.

CMT VS. PRIVATE LABEL: CHOOSING THE RIGHT MODEL

One critical distinction that confuses many founders is the service model. When searching for small batch clothing manufacturers in Vietnam, you will encounter two main terms: CMT and Private Label (FOB).

- CMT (Cut-Make-Trim): You provide everything. You buy the fabric, buttons, zippers, labels, and deliver them to the factory. The factory only sells their labor (cutting and sewing).

- Private Label / FOB (Free On Board): The factory provides a “Full Package.” They source the fabric, develop patterns, buy trims, sew, and pack.

TABLE 3: SERVICE MODEL COMPARISON

| Feature | CMT (Cut-Make-Trim) | Private Label / FOB |

| Fabric Sourcing | You provide (Hard for startups) | Factory provides (Best for startups) |

| Trims (buttons, zips) | You provide | Factory provides |

| Pattern Making | You provide | Factory provides |

| Labels & Tags | You provide | Factory provides |

| Best For | Experienced brands with sourcing teams | Startups & New Brands |

| Minimum Fabric Order | You must buy 300kg+ from mills | Factory consolidates orders |

The Reality: For 90% of new brands, attempting CMT is a mistake. Fabric mills rarely sell small quantities to unknown individuals. Therefore, finding small batch clothing manufacturers in Vietnam that offer Private Label (FOB)services is the most viable path to market.

THE CHALLENGE: WHY DO FACTORIES REJECT LOW MOQ ORDERS?

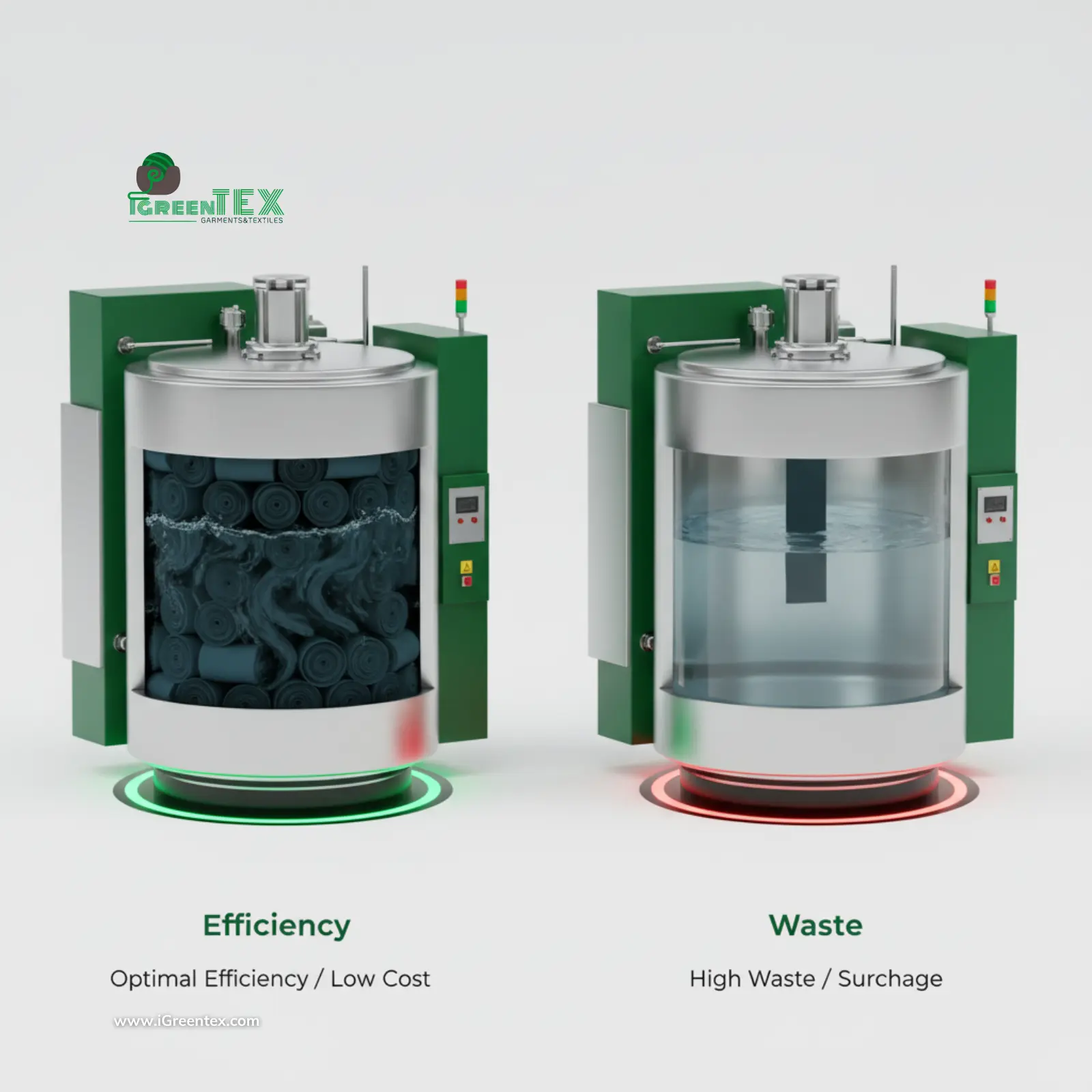

To negotiate effectively, you must understand the factory owner’s perspective. Why do they reject small orders? It is not because they are arrogant or lazy. It is because of the “Efficiency Curve.”

When you ask small batch clothing manufacturers in Vietnam for a quote, they are calculating two main efficiency killers: Line Setup and Fabric Dyeing.

1. The Cost of Line Setup

Industrial garment manufacturing relies on assembly lines. A standard line might have 20 to 40 workers tailored to a specific workflow. To switch a line from sewing Polo Shirts to sewing Hoodies, the mechanics must:

- Change thread colors on 40 machines.

- Adjust tension settings for different fabric thicknesses.

- Re-arrange the seating plan.

This process takes about 4 hours. During those 4 hours, production is zero.

TABLE 4: SETUP COST BREAKDOWN

| Order Size | Setup Time | Fixed Setup Cost | Cost Per Unit (Amortized) | Factory Profitability |

| 10,000 pieces | 4 hours | $200 | $0.02 | High |

| 1,000 pieces | 4 hours | $200 | $0.20 | Medium |

| 100 pieces | 4 hours | $200 | $2.00 | Negative / Loss |

This table explains why a small batch clothing manufacturers in Vietnam must charge a higher unit price. They are not ripping you off; they are covering the fixed setup costs.

2. The Fabric Mill Constraint

This is the “silent killer” of small orders. Garment factories typically do not weave or dye their own fabric; they buy it from fabric mills. Fabric mills operate huge high-pressure dyeing vats.

- The minimum efficient load for a standard dyeing machine is 300kg (approx. 1,000 t-shirts).

- If you only need 50kg for a small order, the machine still runs with the same water, energy, and labor.

TABLE 5: FABRIC DYEING ECONOMICS

| Fabric Quantity | Dyeing Status | Cost Impact | Suitable For |

| 500kg+ | Full Vat (Efficient) | Standard Price | Orders > 1,000 pcs |

| 100 – 300kg | Partial Vat | 30-50% Surcharge | Orders 300 – 800 pcs |

| Under 100kg | Empty Vat | 100-200% Surcharge | Not Recommended |

| Stock Fabric | Already Dyed | No Surcharge | Small Batch Orders |

Understanding these constraints allows you to stop fighting against the factory and start working with them.

SOLUTIONS FOR STARTUPS: HOW TO NAVIGATE LOW MOQ

You are a startup. You cannot order 1,000 pieces yet. Does that mean you cannot produce in Vietnam? Absolutely not. You just need to use specific strategies to work with small batch clothing manufacturers in Vietnam.

Here are three proven strategies we use at iGreen Tex to help clients launch successfully.

Strategy 1: The “Stock Fabric” Hack

This is the single most effective way to lower your MOQ. Instead of asking the factory to dye a custom “Pantone 18-3025” color just for you, ask them: “What fabric do you have in stock?”

Reliable small batch clothing manufacturers in Vietnam usually have “deadstock” or “available stock” left over from large orders.

TABLE 6: STOCK FABRIC VS. CUSTOM FABRIC

| Aspect | Stock Fabric | Custom Dyed Fabric |

| Minimum Order | 50 – 100 pieces | 500 – 1,000 pieces |

| Lead Time | Fast (2-3 weeks) | Slow (6-8 weeks) |

| Dyeing Surcharge | None | $500 – $2,000 |

| Color Options | Limited (Black, White, Navy, Grey) | Unlimited (Any Pantone) |

| Best For | MVP / First Launch | Established Brands |

The Strategy: Launch your first collection using standard colors (Stock Fabric) but focus on high-quality printing, embroidery, or unique fits to differentiate your brand.

Strategy 2: Consolidate Your Designs

A common mistake startups make is trying to launch too many styles at once. They want a T-shirt, a Hoodie, a Polo, and a Jogger. This splits the volume too thin.

TABLE 7: ORDER CONSOLIDATION STRATEGY

| Approach | Styles | Pieces Per Style | Total Volume | Factory Response |

| Bad Plan | 5 Styles | 50 each | 250 Total | ❌ Rejected (5 Setups required) |

| Good Plan | 1 Style (T-shirt) | 250 Total (3 sizes) | 250 Total | ✅ Accepted (1 Setup required) |

| Better Plan | 2 Styles | 150 each | 300 Total | ✅ Accepted (2 Setups required) |

By consolidating your order into fewer styles, you make the production run efficient. You become an attractive partner for small batch clothing manufacturers in Vietnam.

Strategy 3: The “Growth Partner” Pitch

Factories are businesses looking for long-term stability. If you approach them as a “one-time” buyer, they will prioritize you last. You need to sell your vision.

TABLE 8: GROWTH TIMELINE PITCH

| Phase | Timeline | Order Size | Unit Price | Factory Priority |

| Test Launch | Month 1-3 | 200 pieces | $8.00 | Medium |

| Validation | Month 4-6 | 500 pieces | $6.50 | Medium-High |

| Scale Up | Month 7-12 | 1,500 pieces | $5.00 | High |

| Established | Year 2+ | 5,000+ pieces | $4.00 | Very High |

At iGreen Tex, we actively look for founders who have this mindset. We are willing to invest in small batch clothing manufacturers in Vietnam relationships today to build the volume clients of tomorrow.

PRIVATE LABEL SERVICES: BUILDING YOUR BRAND IDENTITY

Finding a factory that accepts small orders is only step one. Step two is ensuring the product looks like your brand, not a generic wholesale item. This is where the Private Label services of small batch clothing manufacturers in Vietnambecome essential.

Even for a run of 100 pieces, branding is non-negotiable for building value.

1. Custom Tags and Labels

Nothing screams “cheap” like a generic size tag.

TABLE 9: LABEL OPTIONS FOR STARTUPS

| Label Type | Description | Cost Per Piece | MOQ | Best For |

| Woven Neck Label | Logo woven into satin/damask | $0.15 – $0.30 | 100 pcs | Premium Brands |

| Heat Transfer | Tagless, printed inside neck | $0.10 – $0.20 | 50 pcs | Activewear / Baby |

| Side Seam Tag | Care instructions + Composition | $0.08 – $0.15 | 100 pcs | Mandatory (EU/US) |

| Hangtag | Brand story on cardstock | $0.20 – $0.50 | 100 pcs | Retail Appeal |

2. Custom Packaging

The unboxing experience is a crucial part of your product’s perceived value.

TABLE 10: PACKAGING OPTIONS

| Package Type | Description | Eco-Friendly | Brand Impact | Cost Estimate |

| Clear Poly Bag | Standard transparent bag | ❌ No | Low | $0.05 |

| Frosted Zip Bag | Semi-transparent with logo | ❌ No | Medium | $0.15 – $0.25 |

| Kraft Paper Bag | Brown paper with window | ✅ Yes | High | $0.20 – $0.30 |

| Biodegradable | Cornstarch material | ✅ Yes | Very High | $0.25 – $0.40 |

3. Pattern Making and Grading

You do not need to be a fashion designer to work with small batch clothing manufacturers in Vietnam. If you send us a reference sample (e.g., “I want the fit of this specific Nike shirt but with longer sleeves”), our technical team will create the sewing pattern.

TABLE 11: PATTERN SERVICES

| Service | Scope of Work | Timeline | Cost Range |

| Pattern Making | Create first pattern from sketch | 3-5 days | $50 – $150 |

| Grading | Develop all sizes (S to XL) | 2-3 days | $30 – $80 |

| Sample Making | Sew first prototype | 5-7 days | $20 – $50 / pc |

THE PRICING REALITY: UNIT COST VS. INVENTORY RISK

We need to have an honest conversation about money. When you search for small batch clothing manufacturers in Vietnam, you might expect the same price as a 10,000-unit order. This is unrealistic.

However, paying a higher unit price is actually a smart financial strategy for startups.

TABLE 12: PRICING COMPARISON & RISK ANALYSIS

| Scenario | Order Size | Unit Price | Total Investment | Inventory Risk | Cash Flow Impact |

| Large Order | 10,000 shirts | $4.00 | $40,000 | Very High | Dangerous |

| Small Batch | 200 shirts | $8.00 | $1,600 | Very Low | Safe for Testing |

| Medium Order | 1,000 shirts | $5.50 | $5,500 | Medium | Good for Growth |

TABLE 13: PRICE PROGRESSION

| Order Phase | Quantity | Expected Unit Price | Reason for Price Drop |

| Test Order | 100 – 200 | $8.00 – $10.00 | High ratio of setup costs. |

| Pilot Run | 300 – 500 | $6.00 – $8.00 | Better line efficiency. |

| First Production | 1,000 | $5.00 – $6.00 | Custom fabric becomes cheaper. |

| Volume Brand | 10,000+ | $3.00 – $4.00 | Maximum efficiency. |

IGREEN TEX’S APPROACH TO SMALL BATCH PRODUCTION

At iGreen Tex, we have structured a specific division of our factory to handle small batch clothing manufacturers in Vietnam requirements. We do not treat small orders as a nuisance. We treat them as R&D (Research & Development).

1. Flexible MOQs

We do not have a hard “No.” Our MOQs are flexible based on fabric choice.

TABLE 14: IGREEN TEX MOQ STRUCTURE

| Product Type | Stock Fabric MOQ | Custom Fabric MOQ | Lead Time |

| Basic T-shirts | 100 pieces | 500 pieces | 3-4 weeks |

| Polo Shirts | 150 pieces | 600 pieces | 4-5 weeks |

| Hoodies | 100 pieces | 500 pieces | 4-6 weeks |

| Joggers | 150 pieces | 600 pieces | 5-6 weeks |

2. Technical Support for Non-Designers

Many founders have great taste but zero technical skills. They do not know what a “Tech Pack” is. We bridge that gap better than most small batch clothing manufacturers in Vietnam.

TABLE 15: TECHNICAL SUPPORT SERVICES

| Support Area | What You Need | What We Provide |

| Tech Pack | Sketches / Ideas | We create digital Tech Packs. |

| Fabric | No knowledge | We send physical swatch books. |

| Sizing | No size chart | We provide standard size charts (US/EU/Asian). |

| Trims | No suppliers | We source all buttons/zippers locally. |

3. Quality Control (QC) for Every Batch

Some factories skip QC on small orders to save money. We do not. Even for small batch clothing manufacturers in Vietnam, quality consistency is vital. A startup cannot afford a 10% defect rate.

TABLE 16: QC PROCESS FOR SMALL BATCHES

| QC Stage | What We Check | Defect Tolerance |

| Fabric Inspection | Color, weight, holes | < 0.5% major defects |

| Pre-Production | Fit, construction, styling | Must be 100% correct |

| Inline Inspection | Sewing quality (seams) | < 2.5% major defects |

| Final Inspection | Measurements, cleanliness | AQL 2.5 Standard |

NEW SECTION: LOGISTICS FOR SMALL BATCHES (AIR VS. SEA)

One area often overlooked when discussing small batch clothing manufacturers in Vietnam is shipping. How do you get 200 shirts from Vietnam to New York or London efficiently?

For small batches, logistics work differently than volume orders.

Option 1: Air Courier (DHL/FedEx/UPS)

- Best For: Orders under 100kg (approx. 300-400 t-shirts).

- Speed: 3-5 days.

- Cost: High (

6−6−9 per kg). - Process: Door-to-door. The factory handles everything.

Option 2: Air Cargo

- Best For: Orders 100kg – 500kg.

- Speed: 5-7 days.

- Cost: Medium (

4−4−6 per kg). - Process: Airport-to-Airport. You need a broker to clear customs.

Option 3: Sea Freight (LCL – Less than Container Load)

- Best For: Orders > 2 CBM (Cubic Meters).

- Speed: 30-45 days.

- Cost: Low, but minimum port fees make it expensive for very small shipments.

- Recommendation: Usually not worth it for orders under 1,000 pieces due to the slow speed and fixed port charges.

As experienced small batch clothing manufacturers in Vietnam, iGreen Tex has negotiated rates with DHL and FedEx to provide discounted shipping for our startup clients.

CASE STUDY: FROM 200 TO 5,000 PIECES

In 2022, a streetwear brand from Melbourne contacted us. They wanted a heavy oversized hoodie. Most small batch clothing manufacturers in Vietnam ignored them because they only wanted 200 pieces.

TABLE 17: GROWTH JOURNEY CASE STUDY

| Year | Order Size | Fabric Type | Unit Price | Result |

| 2022 Q1 | 200 pieces | Stock French Terry (400gsm) | $12.00 | Sold out in 2 weeks. |

| 2022 Q4 | 500 pieces | Stock + 1 Custom Color | $10.00 | Sold out in 3 weeks. |

| 2023 Q2 | 1,000 pieces | Custom Dyed Fabric | $8.50 | Established retail presence. |

| 2024 Q1 | 5,000 pieces | Fully Custom Knit | $6.50 | Quarterly repeat orders. |

The Result: We took the order using Stock Fabric. The unit price was high ($12.00), but the client made a profit because they positioned it as a premium product. Now, they are one of our top clients. This is why we support small batch clothing manufacturers in Vietnam services—we build partners.

CONCLUSION

The barrier to entry for fashion brands has never been lower, provided you find the right partner. The “MOQ Wall” is not invincible. It is a puzzle, and now you have the pieces to solve it.

By using stock fabrics, consolidating your designs, and understanding the economics of production, you can successfully work with small batch clothing manufacturers in Vietnam. You do not need to be a massive corporation to access high-quality manufacturing. You just need to be professional, prepared, and willing to build a relationship.

Do not let the fear of minimums stop your launch. The market rewards those who start.

Ready to launch your brand?

iGreen Tex specializes in helping startups navigate the complexities of production. We are proud to be one of the few reliable small batch clothing manufacturers in Vietnam that offers true Private Label support.

[Contact iGreen Tex] today. Send us your concept, and let’s discuss how we can turn your small batch idea into a big business reality.