- The Due Diligence Framework: How to Truly Vet a Vietnamese Garment Supplier

- Introduction: Beyond the Checklist – Why Most Verification Advice Fails

- Conclusion: From Verification to Partnership

- About iGreen Tex Vietnam

- IGREEN TEX VIETNAM CO LTD

The Due Diligence Framework: How to Truly Vet a Vietnamese Garment Supplier

Introduction: Beyond the Checklist – Why Most Verification Advice Fails

Most articles give you a simple checklist for finding a supplier. But a professional scammer can also prepare to pass a simple checklist. The real problem is not about “ticking the boxes.” It is about knowing how to analyze and interpret what you find. True security comes from a deeper level of understanding. The process of how to verify garment suppliers in Vietnam requires more than a surface-level glance. It demands a structured approach to thinking and decision-making for your brand’s safety.

This article is not another checklist. It is a 3-layer due diligence framework. Due diligence is the essential research you do before a major business decision. Our framework is built from real-world, on-the-ground experience. It helps you move from just collecting information to making smart judgments. We will teach you how to “read” a potential supplier. This is the foundation of the Vietnam clothing factory validation process. Following this guide is the first step in protecting your investment and your brand’s future.

The stakes in this process are incredibly high. A core strategy for Avoiding Clothing Manufacturer Scams in Vietnam is knowing exactly who you are dealing with before any money is transferred. While our comprehensive guide on scams covers the full spectrum of risks, this article focuses on the single most critical preventative measure: a professional verification framework. Think of this guide as the practical “how-to” for the principles discussed in our broader guide on scams.

Learning how to verify garment suppliers in Vietnam is more than a simple check; it requires a complete Vietnam clothing factory validation process. This system is built for thoroughly assessing apparel manufacturers in Vietnam from every angle, from legal documents to their real-world operational capacity. Ultimately, the goal of this guide is to help you master how to verify garment suppliers in Vietnam by using a reliable Vietnam clothing factory validation process. This structured approach to assessing apparel manufacturers in Vietnam is what separates successful brands from cautionary tales.

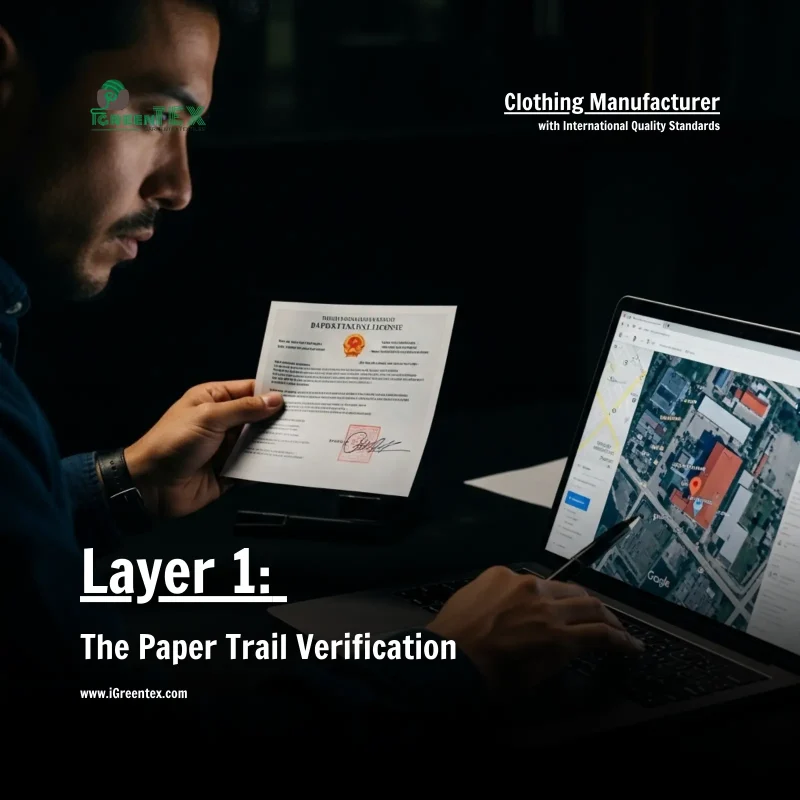

Layer 1: The Paper Trail Verification

The first layer of our framework is about verifying a supplier’s legal existence. We check the consistency and legitimacy of their documents. This is the most basic yet critical filter. It quickly removes obvious fakes and poorly established operations. Mastering this step is fundamental to how to verify garment suppliers in Vietnam. It ensures you are dealing with a real, registered business entity from the very start. The entire Vietnam clothing factory validation process depends on this initial step being done correctly and thoroughly.

Going Deeper Than the Business License

Every legitimate factory in Vietnam has a business license. But you must inspect it with a critical eye, not just accept it.

- The Request: Ask for a clear, high-resolution photo of the original document. It must show the official red stamp. Do not accept a scanned PDF file. PDFs can be easily altered with graphic design software. A photo of the physical paper is harder to fake convincingly.

- The Action: Locate the “Mã số thuế” (Tax Code) on the license. Use this unique code to look up the company on Vietnam’s National Business Registration Portal. A local partner can assist with navigating this Vietnamese-language site.

- The Red Flags: Be very cautious of companies established less than one year ago. Look up their registered address on Google Maps. If it points to a virtual office building, it is a major warning. Finally, check their business status. A “Temporarily Suspended” status is a definite deal-breaker. A proper Vietnam clothing factory validation process starts with these non-negotiable details.

How to Detect Fake Certifications from Vietnam Suppliers

Certifications like WRAP or OEKO-TEX can show a factory’s commitment to ethical practices and quality. However, fraudulent certificates are very common in the industry. Knowing how to detect fake certifications from Vietnam suppliers is a crucial skill.

- The Action: Always ask for the unique certificate number. Also, ask for the official name of the certifying body (e.g., WRAP, SGS, OEKO-TEX). Do not stop there.

- The Verification: Go directly to the certifying body’s official website. Find their public database or directory of certified partners. Use their search tool to look for the factory’s name or certificate number. Never, ever trust a PDF file that the supplier sends to you. Verifying directly with the source is the only safe method. This is a critical skill for assessing apparel manufacturers in Vietnam.

Analyzing the Website and Digital Footprint

A company’s online presence tells a story. You need to check if that story is consistent, professional, and believable. This analysis is a key part of how to verify garment suppliers in Vietnam.

- The Action: Use a free WHOIS lookup tool online. This tool tells you when a website’s domain name was registered. A factory claiming “20 years of experience” with a website that is only one year old is a major red flag.

- The Cross-Check: Search for the company’s name on LinkedIn. Do they have a professional company page? Do their key employees have profiles with consistent, verifiable work histories? A lack of a professional digital footprint is suspicious in today’s market. This detailed check is essential for the Vietnam clothing factory validation process.

This table summarizes what to look for during your paper trail verification.

| Element | Green Flag (Good Sign) | Red Flag (Warning Sign) |

| Business License | “Active” status, over 3 years old | Recently established, virtual office address |

| Certifications | Verifiable on the official issuer’s website | Only provides a PDF, refuses to give ID number |

| Website | Old domain age, consistent information | New domain, stock photos, no team info |

Layer 2: The Operational Reality

After verifying the paperwork, you must confirm their real-world capabilities. This layer of due diligence answers a critical question: Can they actually make your product to your standards? This stage moves beyond documents and into the practicalities of production. A thorough Vietnam clothing factory validation process must include these operational checks. It is essential for assessing apparel manufacturers in Vietnam accurately and avoiding future disappointment.

How to Assess Production Capacity of Garment Factories in Vietnam

Learning how to assess production capacity of garment factories in Vietnam is about asking smart questions. Do not ask a generic question like, “What is your monthly capacity?” A good factory knows this is a vague question. A lazy or dishonest one will give you an inflated number.

- The Smart Question: Ask something highly specific to your product. For example: “For a basic 180 GSM cotton t-shirt, from cutting to packing, how many units can one of your 20-worker sewing lines finish in an 8-hour shift?”

- The Analysis: A supplier with real operational knowledge will give you a confident and realistic answer. They might even ask for clarifying details about the t-shirt’s construction. A scammer or a disorganized factory will hesitate. They might give a vague, unbelievable number. This simple question tests their real-world, hands-on experience. This is a core component of how to verify garment suppliers in Vietnam.

Conducting an Effective Virtual Factory Audit Vietnam Garment Industry

A live video call is one of your most powerful tools. But you must lead the virtual factory audit Vietnam garment industry with purpose and a critical eye.

- The Request: Schedule an initial video call. But also ask for an unscheduled, spontaneous one at a later date. This prevents them from staging a small, clean area just for you.

- The “Impossible Task”: During the live call, ask for a task that is impossible to fake. For example: “Can you please write my name and today’s date on a piece of fabric scrap and place it under the needle of a running Juki sewing machine?” or “Please show me the fabric inspection machine in operation right now.”

- The Observation: Look at the details in the background. Is the factory floor clean and organized? Are workers following safety rules? Are fabric rolls and finished goods stored properly, or are they thrown in piles on the floor? This visual evidence is a key part of how to verify garment suppliers in Vietnam.

Due Diligence Through the Sampling Process

The way a supplier handles your sample request reveals their technical skill and their attitude. It’s a preview of your future working relationship.

- The Action: Send them a technical package (a “tech pack”). A tech pack is a detailed document with all the design specifications for your product. Intentionally include one or two slightly complex or ambiguous technical details.

- The Analysis: Do they ask smart questions to clarify the details? Or do they just agree to everything and then produce an incorrect sample? A great manufacturing partner will question your tech pack. They will offer suggestions for improvement. This shows they are thinking like a partner, not just an order-taker. This is a vital part of assessing apparel manufacturers in Vietnam. A proactive approach here is a very positive sign.

Layer 3: The Commercial Viability

This is the most critical layer, and it is the one most businesses overlook. A factory might be real and technically skilled. But are they a good business partner? This layer assesses their commercial professionalism, communication, and long-term reliability. Your brand’s success depends on their viability as a partner. This final stage of the Vietnam clothing factory validation process is crucial for building a sustainable business.

Analyzing Quotations: Warning Signs in Garment Supplier Quotations Vietnam

A price quote is more than just a number. It is a reflection of a supplier’s professionalism and business practices. You must look for the hidden warning signs in garment supplier quotations Vietnam.

- Red Flag #1: Too Fast: A detailed quote delivered in just a few hours for a complex product is a warning. It shows they did not actually calculate the costs. They likely gave you a low number just to get your attention.

- Red Flag #2: Too Vague: The quote should have a detailed cost breakdown. It must separate the costs for fabric, CMTP (Cut, Make, Trim, Pack), and specific accessories. A single total number is a sign of unprofessionalism or that they are hiding high margins.

- Red Flag #3: Too Cheap: A price that is 30-40% lower than the market average is a major warning. This is a classic sign of a “bait-and-switch” tactic. It can also mean they plan to use poor-quality, rejected materials. A professional price quote is a key element in how to verify garment suppliers in Vietnam.

This table helps compare professional and suspicious quotations.

| Element | Professional Quotation | Suspicious Quotation |

| Detail | Clear breakdown of fabric, CMTP, accessories | A single, all-inclusive price |

| Terms | Clearly stated Incoterms (e.g., FOB, EXW) | Vague or missing commercial terms |

| Price | Realistic and justifiable for the quality | Unbelievably cheap compared to others |

Evaluating Communication Professionalism

Good communication is the backbone of a successful production partnership. It is a clear indicator of how they will behave when problems arise.

- Responsiveness: Do they reply to your emails within 24 business hours? Is their English clear and professional, or is it confusing?

- Proactiveness: Do they provide you with updates on their own? Or do you always have to be the one asking for the status of your project? A proactive partner anticipates your questions and keeps you informed.

- Problem-Solving: When an issue arises, do they present a solution? Or do they simply report the problem and wait for you to fix it from thousands of miles away? A great partner solves problems with you. This is a true test when assessing apparel manufacturers in Vietnam.

The Safety Net: When to Use a Third-Party Service?

As you can see, this framework requires significant time and expertise. This is why some brands consider using a third-party inspection service. The process of using third-party garment supplier verification Vietnam is an option, but it has critical limitations you must understand.

Services like SGS, Intertek, or Bureau Veritas are well-known in the industry.

- The Advantage: They can provide an objective, on-site report about a factory’s condition on a specific day. This can be a useful data point in your Vietnam clothing factory validation process. It can confirm the existence of machinery or check a finished batch of goods.

- The Critical Disadvantage: They are inspectors, not managers. They will report a problem, but they will not work with the factory every day to fix the problem. They will not prevent future problems from happening. Using these services for every step of production can also become very expensive. They provide a snapshot, not continuous oversight. A snapshot is not enough when learning how to verify garment suppliers in Vietnam for a long-term partnership.

Conclusion: From Verification to Partnership

Supplier verification is not a one-time task you complete and forget. It is a continuous process of building confidence and managing risk. This 3-layer due diligence framework gives you the tools to build a strong foundation. It helps you ask the right questions and analyze the answers like a seasoned expert. But for long-term success and peace of mind, you need more than just a good supplier. You need a true production partner on the ground in Vietnam. This mindset shift changes the entire dynamic of assessing apparel manufacturers in Vietnam.

That is where iGreen Tex is different. We are not just another factory you need to vet. We are a comprehensive Production Partner. Our entire service is built around this 3-layer due diligence framework. We perform these checks as a standard, integrated part of our process for every client. We don’t just help you find a factory; we manage the risk for you. We are your team on the ground. We make the complex process of how to verify garment suppliers in Vietnam simple and secure for you.

Ready to build your brand on a foundation of certainty?

Does this process feel overwhelming? Let our experts handle it for you. Schedule a complimentary Project Risk Assessment today. We will show you how this professional framework can be applied directly to your specific project, giving you clarity and confidence.

About iGreen Tex Vietnam

iGreen Tex Vietnam is a trusted fashion and textile manufacturer based in Vietnam, specializing in high-quality sportswear and casual apparel for global markets. We provide OEM manufacturing services, supporting brands to design, develop, and produce customized garments that meet international quality standards.

Our production focuses on sustainability and eco-friendly practices, using certified fabrics and advanced techniques to reduce environmental impact. From material sourcing to final inspection, every stage of manufacturing follows strict quality control processes to ensure flawless results. With years of experience in Vietnam sportswear manufacturing, we understand the demands of global clients and changing fashion trends.

Our factory operates with modern equipment and a dedicated team to deliver products on time and at competitive pricing. Partnering with iGreen Tex means working with a reliable supplier who combines innovation, quality, and responsibility. We help your brand scale effectively by producing garments that resonate with today’s conscious consumers worldwide.

If you want to read more information about canvas bags, and if you want to tote bags at Ho Chi Minh City, you can see it here!!!

To view product information click here

Visit our website to learn more about our products and services: IGREEN TEX

IGREEN TEX VIETNAM CO LTD

Address: No. 6 – 6A, D52 Street, Bay Hien Ward, Ho Chi Minh City, Vietnam

E-mail: Info@iGreentex.com

WhatsApp/Viber/Zalo: +84 (0) 938.045.900