iGreen Tex Vietnam's Commitments

Global Quality Standards

Rigorous quality control processes ensure every garment meets international manufacturing standards. From fabric sourcing to final inspection, we maintain consistent quality across all production runs.

Expert Consultation

Our experienced team provides comprehensive guidance on fabric selection, design optimization, sizing standards, and production planning to bring your vision to market successfully.

Reliable Delivery

Streamlined production workflows and established logistics partnerships guarantee your orders arrive on schedule. We understand timing is critical for your business success.

Products Warranty

Every product comes with comprehensive warranty coverage against manufacturing defects. Our commitment to quality extends beyond delivery with dedicated after-sales support.

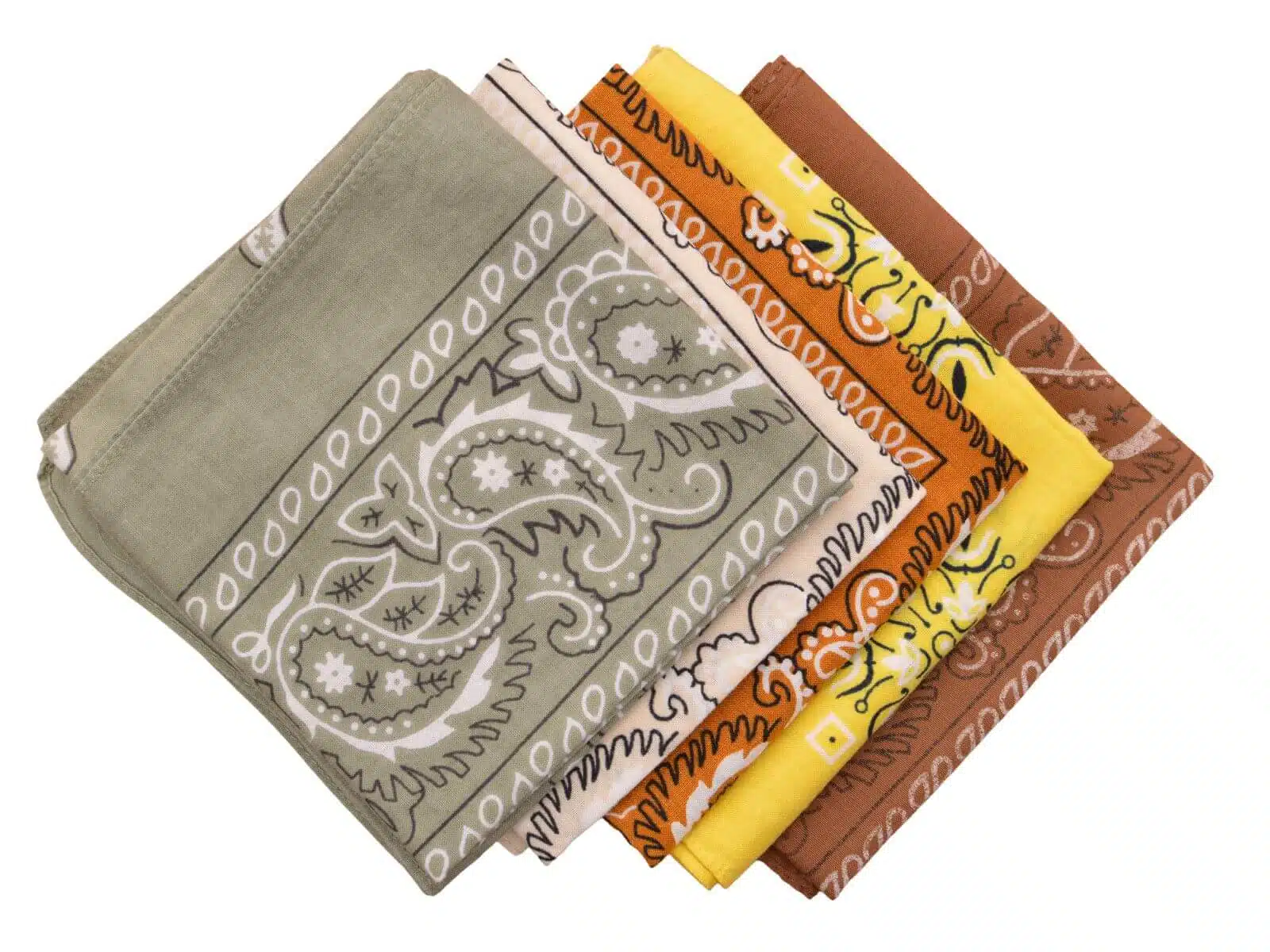

Manufacturing Bandanas & Headbands: Small Accessories, Big Impact

At iGreen Tex Vietnam, we produce bandanas and headbands with moisture-wicking fabrics and secure-fit designs. Our lightweight materials stay comfortable during sports and outdoor activities. Custom patterns and colors help brands stand out in the accessories market.

Need eye-catching headwear accessories?

iGreen Tex Vietnam's Manufacture Process

Receive Samples and Detailed Requirements

Collect all sample items and specific customer requirements to ensure clear understanding before production begins.

Approve Materials and Create Sample

Review and approve fabric and materials, then make a sample to ensure design and quality meet requirements before production.

Cut Fabric and Prepare Details for Production

Cut fabric according to patterns and prepare all necessary components to start the manufacturing process.

Sewing, Printing, and Quality Inspection”

Sew garment pieces together, print designs, and carefully inspect to ensure quality standards are met.

Cleaning, Packing, and Delivery

Clean finished products, carefully pack them, and arrange timely delivery to customers.

Featured Products

Manufacturing

Aprons

Used in kitchens, cafes, salons, or workshops. Often customized with logos for staff uniforms.

Manufacturing

Towels

Cotton or microfiber towels for hotels, spas, gyms, or giveaways. Can be branded or plain.

Manufacturing

Fabric Bags

Reusable cotton, canvas, or polyester bags for shopping, promotions, or packaging.

Manufacturing

Sleep Masks / Eye Covers

Used in travel kits or hotels. Usually soft and lightweight.

Manufacturing

Caps and Beanies

Fabric hats, including caps with visors or soft beanies for warmth.

Discover More Apparel Solutions We Manufacture

Clients Feedback

See what customers have to say about our manufacturing capabilities. From startup brands to established retailers, discover how iGreen Tex delivers consistent quality and reliable partnerships that drive business growth.