- How Coffee Waste Is Turned Into a Functional Fabric

- What is Coffee Fabric? Understanding Coffee Ground Technology in Textiles

- Key Properties and Functional Benefits of Coffee Fabric Material

- Who Manufactures Coffee Fabric? Key Suppliers and Origin

- Cost Analysis: Current Market Pricing for Coffee Fabric

- Cost Comparison: Coffee Fabric vs. Traditional Polyester and Cotton

- Direct Price Comparison

- Production Cost Factors

- Performance Value Analysis

- Total Cost of Ownership

- Market Positioning

- Major Applications: What Apparel Categories Work Best with Coffee Fabric?

- Primary Apparel Categories

- Applications to Avoid

- Product Development Recommendations

- Technical Considerations for Production

- The Manufacturing Process: From Coffee Grounds to Finished Yarn

- Market Feedback: Consumer Perception and Sustainability Impact

- Consumer Reception in Vietnam

- Corporate Adoption

- Sustainability Impact

- Market Challenges (Rarely Advertised)

- Consumer Segment Analysis

- Frequently Asked Questions (FAQ) About Sourcing Coffee Fabric

- General Questions About Coffee Fabric

- Pricing & Commercial Terms

- Technical Specifications & Quality

- Production Capabilities & Manufacturing

- Logistics & Export

How Coffee Waste Is Turned Into a Functional Fabric

At first listen to about “coffee fabric” glance, the idea sounds unusual, even hard to believe. Turning something discarded into something wearable challenges how people define modern textiles. Many readers first encounter this topic through curiosity, not an intention to buy. They want to know how waste can quietly enter the fashion industry. From there, curiosity expands into who developed the idea and why it gained attention.

What is Coffee Fabric? Understanding Coffee Ground Technology in Textiles

Coffee Fabric is a sustainable performance textile engineered by fusing post-consumer coffee grounds with recycled polyester from PET bottles. Rather than a surface coating, the manufacturing process embeds nano-scale coffee particles directly into the fiber’s core structure. This creates a permanent, chemical-free yarn that naturally controls odors, dries 200% faster than cotton, and blocks UV rays. It serves as a circular solution for brands looking to reduce waste while maintaining high functionality in activewear and apparel.

Key Technical Facts:

- Definition: A composite technical fiber made from roasted coffee residue (processed at 160°C–220°C) and recycled polymer.

- Industrial Names: Industrially known as S.Café or simply coffee fiber.

- Origin: Invented in Taiwan (2008) by Jason Chen, founder of Singtex, after discovering coffee’s natural deodorizing capabilities.

Key Properties and Functional Benefits of Coffee Fabric Material

Coffee fabric uses micro-porous structure from ground coffee beans. This creates functional advantages for performance wear.

Core Performance Properties

| Property | Performance | How It Works |

| Odor Control | 3x better than standard fabric | Micro-pores trap body odors (20.38% in 2 hours) |

| Fast Drying | 200% faster than cotton | Rapid moisture wicking through porous structure |

| UV Protection | Blocks UVA/UVB rays | Coffee particles reflect and refract UV radiation |

| Cooling Effect | Reduces temperature 1-2°C | Enhanced breathability and airflow |

Properties remain effective after washing and sun exposure.

Material Composition

Standard coffee fabric blend:

- 5% recycled coffee grounds (post-consumer waste)

- 95% recycled PET polyester (from plastic bottles)

One hoodie contains 3 cups of coffee grounds + 10 plastic bottles.

Environmental Benefits

Resource Savings:

- Processing temperature: 160°C (vs. 600°C conventional yarn)

- Water usage: Zero (cotton needs 2,700 liters per shirt)

- Carbon emissions: 48% reduction vs. virgin polyester

Waste Management:

- Diverts coffee grounds from landfills

- Prevents methane release (30x worse than CO2)

- 100% biodegradable structure

Best Applications

- Activewear – Fast drying, odor control during exercise

- Outdoor Gear – UV protection, temperature regulation

- Uniforms – Antibacterial properties reduce washing

- Daily Wear – Wrinkle resistance, color retention

Limitations (Rarely Mentioned)

Cost: 20-50% more expensive than cotton/polyester

Sensitivities: Residual caffeine may affect sensitive people; rare skin irritation reports

Durability: Color fades faster; properties degrade with washing; less elastic than pure polyester

Performance Limits: Not fully waterproof; coffee scent may bother some users

Microplastic Issue: 95% PET still sheds microplastics despite biodegradable claims

Who Manufactures Coffee Fabric? Key Suppliers and Origin

Coffee fabric production is concentrated in Taiwan and Vietnam, with growing presence in the United States.

Taiwan: The Technology Pioneer

Singtex Industrial Co., Ltd. invented coffee fabric technology in 2009. They created the patented S.Café® process. This process converts used coffee grounds into textile fibers. Singtex combines recycled coffee grounds with recycled polyester. The process uses low temperature and high pressure. Over 110 global brands use their technology. These include Patagonia, North Face, Adidas, and Timberland.

Nam Liong Global Corporation is Taiwan’s largest textile manufacturer. Founded in 1972, they serve Nike, 3M, and Decathlon. They integrate S.Café® technology into protective fabrics. Their specialty is S.Café® Kevlar® for industrial use.

JIA-ZHAN Textile Technology has operated since 2000. They focus on footwear textiles. Their Café Yarn offers odor control and UV protection. They are members of the U.S. Cotton Trust Protocol.

Vietnam: The Growing Manufacturing Hub

Faslink JSC leads Vietnamese production with 17 years of experience. They produce ALL ABOUT CAFÉ® using licensed S.Café® technology. Their factory processes 500+ products monthly. They operate with 300+ European-imported machines. Faslink holds GRS certification and serves 500+ businesses.

WELL Fabric supplies both raw materials and finished fabrics. They have over 10 years of specialized experience. WELL Fabric holds OEKO-TEX and GRS certifications. They offer flexible minimum order quantities.

Greenyarn started in 2021 as Vietnam’s first sustainable textiles company. They distribute S.Café coffee yarn under Singtex license. They make eco-friendly materials accessible to local manufacturers.

Ecosilky was established in 2020 following slow fashion principles. They produce fabrics from agricultural waste including coffee grounds. They also work with banana, pineapple, and lotus fibers. Ecosilky holds GOTS certification.

Thai Son Vietnam manufactures both fabric and finished garments. They specialize in transforming coffee fabric into activewear and jackets. They work directly with brands on product development.

United States: Consumer-Facing Brands

Coalatree operates from Utah and manufactures sustainable apparel. Each hoodie uses 3 cups of coffee grounds and 10 plastic bottles. Their factories are bluesign®-certified. They focus on hoodies, joggers, and denim.

Virus Action Sport Performance specializes in athletic compression wear. Founded in 2009, they developed Coffee Char technology. They integrate recycled coffee grounds into performance fabrics. Their EcoNuve™ line serves serious athletes.

Production Scale and Supply Chain

Global production reaches approximately 100 tons monthly. Standard coffee fabric contains 5% recycled coffee grounds and 95% recycled PET. Taiwan controls the core technology. Vietnam dominates manufacturing capacity. US brands focus on direct-to-consumer markets. This supply chain now serves 110+ international brands worldwide.

Cost Analysis: Current Market Pricing for Coffee Fabric

Coffee Yarn (Wholesale)

Bulk orders (1,000kg minimum):

- $15-25 USD/kg (₫370,000-615,000/kg)

- Global average: $20 USD/kg

- Premium S.Café® grades cost more

Vietnam example (Synex VN):

- MOQ: 280kg per color

- Capacity: 70 tons monthly

- Price: Contact for quote

Finished Fabric (Per Meter)

| Market | Fabric Type | Price | MOQ/Notes |

|---|---|---|---|

| India | 44″ standard | $3.35/m | Samundar Fabrics |

| Vietnam | White retail | ₫199,000/m | Single purchase |

| Vietnam | Premium jersey | Contact | 1.8-2m per kg |

| China | Nylon blend | $8.50-35.50/m | 2,000 yards min |

| Global | S.Café wholesale | $5-15/m | Varies by weight |

Price Comparison

Cotton flannel: $4-5/m (2-3x cheaper)

Recycled polyester: $3-7/m

Coffee fabric: $5-15/m (premium for performance)

What Affects Price

- Small orders: +30% cost vs. bulk

- Certifications: OEKO-TEX/GRS adds ~20%

- Location: Vietnam cheaper (local coffee waste)

- Customization: GSM weight, colors, finishing

Market Update (January 2026)

Vietnam coffee beans: ₫98,500/kg (rising toward ₫100,000/kg)

Despite raw material increases, fabric prices stay stable. Sustainable demand supports current pricing.

Cost Comparison: Coffee Fabric vs. Traditional Polyester and Cotton

Direct Price Comparison

| Factor | Coffee Fabric | Cotton | Recycled Polyester |

|---|---|---|---|

| Wholesale Price | $5-15/meter | $4-5/meter | $3-7/meter |

| Yarn Price | $15-25/kg | $8-12/kg | $10-15/kg |

| Premium vs. Cotton | +20-50% | Baseline | +10-30% |

| MOQ Impact | High (30% increase if low) | Moderate | Moderate |

Production Cost Factors

| Cost Element | Coffee Fabric | Cotton | Recycled Polyester |

|---|---|---|---|

| Processing Temperature | 160°C | 600°C | 600°C |

| Energy Consumption | Low | High | High |

| Water Usage | Zero (uses waste) | 2,700L per shirt | Low |

| Raw Material Source | Coffee waste + PET bottles | Agricultural (water-intensive) | Recycled plastic |

| Carbon Emissions | 48% lower than virgin poly | Moderate | Lower than virgin |

Performance Value Analysis

| Feature | Coffee Fabric | Cotton | Recycled Polyester |

|---|---|---|---|

| Drying Speed | 200% faster | Slow (holds moisture) | Fast |

| Odor Control | Natural, permanent | Moderate | Requires chemical treatment |

| UV Protection | High (built-in) | Low | Medium |

| Durability | Good (fades over time) | Excellent | Best |

| Antibacterial | Yes (natural polyphenols) | No | Only with treatment |

| Biodegradability | Yes | Yes | No (microplastics) |

Total Cost of Ownership

| Consideration | Coffee Fabric | Cotton | Recycled Polyester |

|---|---|---|---|

| Initial Purchase | Highest | Lowest | Medium |

| Washing Frequency | Lower (odor control) | Higher | Medium |

| Maintenance Cost | Lower long-term | Medium | Medium |

| Lifespan | 2-3 years | 3-5 years | 5+ years |

| End-of-Life | Biodegradable | Biodegradable | Landfill/recycle only |

Market Positioning

| Application | Best Choice | Why |

|---|---|---|

| Budget Activewear | Recycled Polyester | Balance of cost and performance |

| Premium Sportswear | Coffee Fabric | Natural performance features |

| Mass Market Basics | Cotton | Lowest upfront cost |

| Sustainable Brands | Coffee Fabric | Environmental story + function |

| Industrial Uniforms | Coffee Fabric | Odor control reduces washing |

Major Applications: What Apparel Categories Work Best with Coffee Fabric?

Primary Apparel Categories

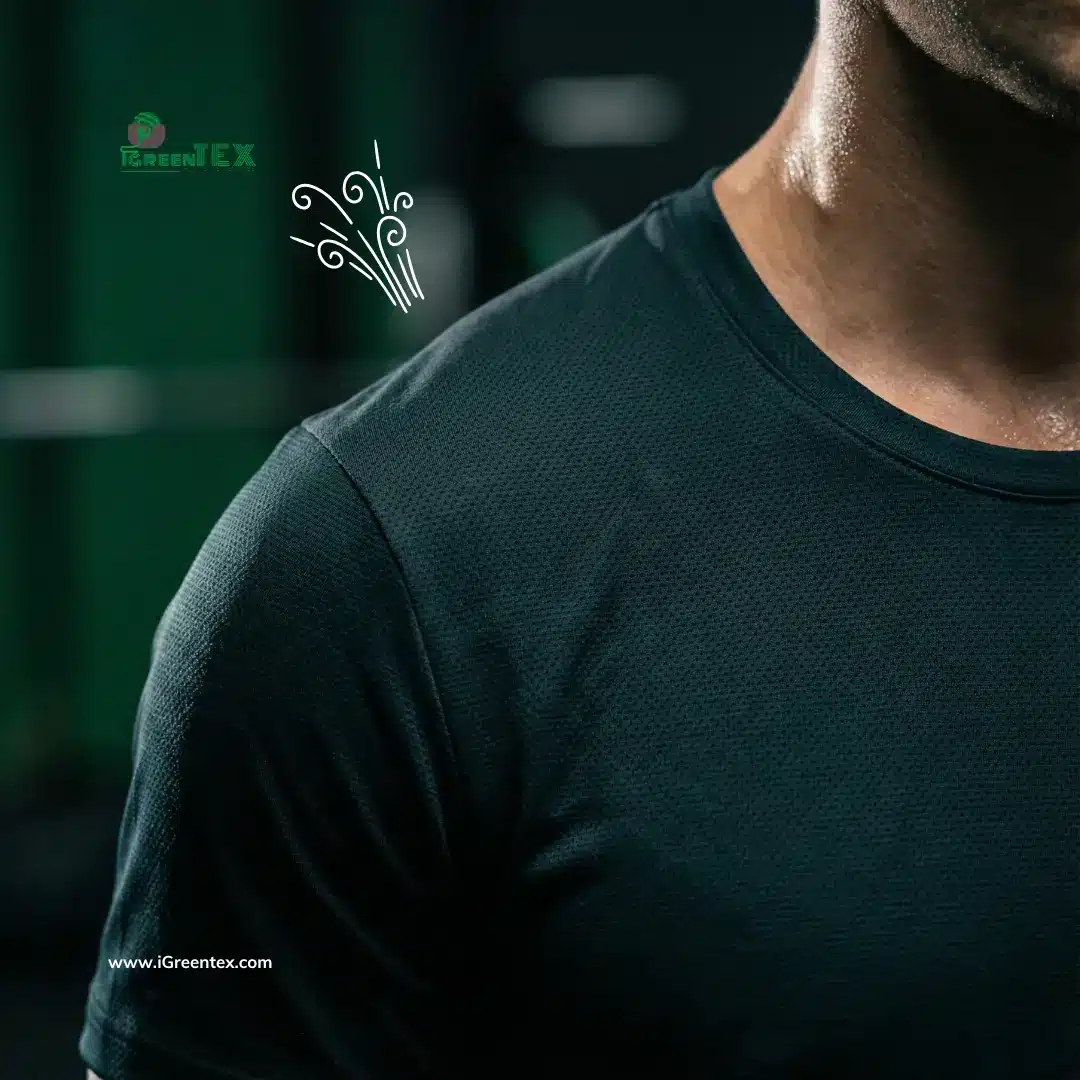

Activewear & Performance Sportswear

Why Coffee Fabric Excels:

- Fast drying prevents moisture buildup during workouts

- Natural odor control reduces post-exercise smell

- Cooling effect maintains comfortable body temperature

- Lightweight structure allows unrestricted movement

Recommended Products:

- Running shirts and shorts

- Gym t-shirts and tank tops

- Yoga pants and leggings

- Sports bras and compression wear

- Training hoodies

Production Advantage: Coffee fabric’s 200% faster drying time makes it superior to cotton for sweat-intensive activities.

See coffee fabric activewear samples and MOQ requirements for your brand’s sportswear line.

Outdoor & Adventure Gear

Why Coffee Fabric Works:

- UV protection for sun exposure during hiking and camping

- Quick-dry properties essential for unpredictable weather

- Odor resistance during multi-day trips without washing

- Breathability for temperature regulation

Recommended Products:

- Hiking t-shirts and base layers

- Trail running apparel

- Fishing shirts with UV protection

- Travel clothing for backpackers

- Lightweight outdoor jackets

Technical Benefit: Built-in UV blocking eliminates need for chemical treatments that wash out over time.

Request tech pack review for outdoor gear using coffee fabric specifications.

Corporate & Service Uniforms

Why Coffee Fabric Reduces Costs:

- Antibacterial properties extend wear between washes

- Odor control maintains professional appearance longer

- Wrinkle resistance reduces maintenance time

- Color retention after repeated laundering

Recommended Products:

- Restaurant server uniforms

- Retail staff polo shirts

- Healthcare scrubs (non-medical grade)

- Hotel and hospitality uniforms

- Corporate branded t-shirts

Long-term Value: Reduced washing frequency lowers operational costs for uniform programs.

Contact us for uniform program pricing with coffee fabric options.

Casual & Lifestyle Wear

Why Consumers Choose Coffee Fabric:

- Sustainable story resonates with eco-conscious buyers

- All-day comfort for daily activities

- Natural temperature regulation

- Easy care maintenance

Recommended Products:

- Casual t-shirts and polos

- Everyday hoodies and sweatshirts

- Lounge wear and athleisure

- Travel-friendly basics

- Weekend casual shirts

Market Positioning: Premium casual wear targeting sustainability-focused consumers willing to pay 20-30% more.

Explore our private label services for sustainable lifestyle brands.

Applications to Avoid

Coffee fabric performs poorly in these categories:

| Category | Why It Doesn’t Work |

|---|---|

| Formal Business Wear | Structure and drape insufficient for tailored garments |

| Heavy Workwear | Durability lower than pure polyester or canvas |

| Waterproof Outerwear | Moisture-wicking design contradicts waterproof needs |

| Luxury Evening Wear | Casual texture unsuitable for formal aesthetics |

| Children’s Sleepwear | Residual caffeine concerns for sensitive young skin |

Product Development Recommendations

For Fashion Startups & Emerging Brands

Start with: Basic t-shirts and hoodies (MOQ ~1,000-2,000 pcs/style)

Coffee fabric works well for:

- Testing sustainable product lines

- Building eco-conscious brand identity

- Differentiating from competitors using standard materials

Fabric weight suggestion: 150-180 GSM for t-shirts, 200-250 GSM for hoodies

Get MOQ flexibility consultation for small batch production with coffee fabric.

For Established Retailers & Brands

Scale with: Complete activewear collections or uniform programs

Coffee fabric supports:

- Premium sustainable product tiers

- Performance lines with natural features

- Large-volume uniform contracts

- Private label expansion

Sourcing advantage: Vietnam manufacturers offer competitive pricing with local coffee waste access.

Schedule sourcing assessment to evaluate coffee fabric for your existing product lines.

For B2B Distributors & Wholesalers

Focus on: Performance wear and corporate uniform segments

Coffee fabric opportunities:

- Supply eco-conscious retailers

- Service uniform distributors

- Corporate gift and promotional markets

- Sustainable apparel wholesalers

Certification priority: Ensure GRS and OEKO-TEX certification for B2B credibility.

Request wholesale fabric samples with certification documentation.

Technical Considerations for Production

Fabric Specifications:

- GSM range: 150-200 for lightweight, 200-280 for heavyweight

- Blend ratio: Standard 5% coffee grounds + 95% recycled PET

- Color options: Custom dyeing available (affects MOQ)

- Finishing: Moisture-wicking and anti-pilling treatments compatible

Quality Control Focus:

- Verify coffee particle distribution consistency

- Test odor control performance before bulk production

- Check color fastness after multiple wash cycles

- Confirm UV protection levels meet claims

Lead Times:

- Yarn sourcing: 4-6 weeks for custom blends

- Fabric production: 3-4 weeks after yarn delivery

- Garment manufacturing: 4-6 weeks depending on complexity

The Manufacturing Process: From Coffee Grounds to Finished Yarn

Stage 1: Coffee Ground Collection & Preparation

Raw Material Sourcing:

- Used coffee grounds collected from cafés, restaurants, and coffee shops

- Post-consumer waste diverted from landfills

- Grounds dried to remove residual moisture

- Quality inspection removes contaminants

Processing Requirements:

- Grounds must be completely dried (moisture content below 10%)

- Particle size standardized through grinding

- Metal and plastic contaminants removed

- Storage in dry conditions before processing

Environmental Impact: Every ton of coffee grounds prevents methane emissions (30x more potent than CO2) from landfill decomposition.

Stage 2: Coffee Ground Treatment & Activation

Patented S.Café® Technology (Singtex Method):

- Coffee grounds undergo high-pressure, low-temperature treatment

- Processing temperature: 160°C (vs. 600°C for conventional yarn)

- Creates micro-porous structure for functional properties

- Activates natural oils and compounds in coffee particles

Key Chemical Process:

- No harsh chemicals added during activation

- Natural coffee polyphenols preserved for antibacterial properties

- Caffeine content neutralized or minimized

- Coffee particles reduced to nano-scale size

Energy Efficiency: Low-temperature processing reduces energy consumption by approximately 60% compared to virgin polyester production.

Stage 3: Polymer Blending & Masterbatch Creation

Material Combination:

- Recycled PET plastic bottles processed into polymer chips

- Treated coffee grounds blended with PET at molecular level

- Standard ratio: 5% coffee grounds + 95% recycled polyester

- Masterbatch pellets created for spinning

Quality Control Points:

- Consistent coffee particle distribution verified

- Polymer viscosity tested for spinning compatibility

- Color uniformity checked across batches

- Moisture content confirmed below specification limits

Innovation Note: Advanced formulations like BIOTEC™ add castor bean polymers for enhanced biodegradability.

Stage 4: Melt Spinning & Fiber Extrusion

Spinning Process:

- Masterbatch pellets melted at controlled temperature

- Molten polymer extruded through spinnerets

- Coffee particles embedded within fiber structure

- Fibers cooled and solidified into continuous filaments

Fiber Specifications:

- Denier range: Typically 75D-150D for apparel

- Filament count: Single or multi-filament options

- Texture: Can be textured for stretch or bulk

- Color: Natural beige or custom dyed

Technical Result: Micro-porous coffee particles create channels within fiber for moisture wicking and odor absorption.

Stage 5: Yarn Formation & Texturing

Yarn Construction Methods:

Spun Yarn Process:

- Fibers cut into staple lengths

- Blended with other fibers if needed

- Spun into continuous yarn using ring or open-end spinning

- Suitable for cotton-like hand feel

Filament Yarn Process:

- Continuous filaments twisted together

- Air-jet or mechanical texturing for bulk

- Creates smooth, performance-oriented yarn

- Ideal for activewear applications

Yarn Specifications:

- Count range: Ne 20-40 for woven, Ne 10-30 for knits

- Twist level: Adjusted for fabric end-use

- Ply options: Single, 2-ply, or multi-ply

- Finish: Oil or wax applied for knitting/weaving

Stage 6: Quality Testing & Certification

Performance Verification:

| Test Parameter | Standard | Purpose |

|---|---|---|

| Odor Absorption | 20.38% in 2 hours | Confirms functional performance |

| UV Protection | UPF 50+ rating | Verifies sun protection claim |

| Moisture Wicking | Drying speed test | Validates fast-dry properties |

| Color Fastness | Grade 4-5 minimum | Ensures durability |

| Tensile Strength | Similar to standard PET | Confirms usability |

Market Feedback: Consumer Perception and Sustainability Impact

Coffee fabric generates strong positive feedback from consumers and brands globally. Over 40 brands now sell millions of coffee fabric products.

Consumer Reception in Vietnam

Sales Performance: Vietnamese brand Coolmate sold over 15,000 coffee fabric polo shirts at under ₫300,000 each. Customers value cooling effects, quick-drying, UV protection, and odor control.

Popular Brands Using Coffee Fabric:

- Routine, Owen, Yody: Polo and sport shirts (up to ₫500,000)

- Faslink: Supplied 700,000 meters in first year

- Current reach: 3+ million garments across 40+ brands

Customer Feedback:

- “Hand feel” improved after 3 product iterations to match local preferences

- Consumers praise breathability and odor resistance for daily and sport use

- Gen Z particularly values sustainability combined with style

Corporate Adoption

ESG-Driven Purchases:

- Multinational corporations in Vietnam order coffee fabric uniforms

- Starbucks and 7-Eleven use coffee fabric globally for staff apparel

- Corporate buyers prioritize sustainability credentials alongside performance

Sustainability Impact

Environmental Benefits Consumers Value:

Waste Reduction: Vietnam produces 1.78 million tons of coffee annually. 10% domestic consumption generates substantial waste grounds. Coffee fabric diverts this waste from landfills.

Circular Economy Appeal:

- Converts coffee waste into functional textiles

- Prevents methane emissions from decomposing grounds

- Supports Net Zero goals through low-energy production

Green Fashion Positioning: Coffee fabric ranks alongside lotus and banana fabrics as Vietnam’s sustainable textile innovations. Industry association VITAS reports rising demand for eco-materials driven by consumer preference.

Market Challenges (Rarely Advertised)

Price Barrier: Coffee fabric costs 20-50% more than standard materials. This premium limits mass market adoption.

Example: Coolmate uses 60% recycled polyester instead of coffee fabric for broader affordability. Price remains the primary barrier to everyday wear adoption.

Scale Limitations: Premium positioning restricts market penetration. Consumers want lower costs for regular wardrobe items, not just specialty activewear.

Consumer Segment Analysis

| Segment | Reception | Purchase Driver |

|---|---|---|

| Gen Z | Highly positive | Sustainability + style combination |

| Active lifestyle consumers | Very positive | Performance features (odor control, UV) |

| Corporate buyers | Positive | ESG compliance requirements |

| Budget-conscious shoppers | Limited interest | Price premium too high |

| Mass market | Awareness growing | Waiting for lower price points |

Frequently Asked Questions (FAQ) About Sourcing Coffee Fabric

General Questions About Coffee Fabric

Q: What exactly is coffee fabric, and how does it work?

iGreen Tex Vietnam: Coffee fabric combines 5% recycled coffee grounds with 95% recycled polyester. We source coffee waste locally in Vietnam and process it into functional textile fibers. The coffee particles create a micro-porous structure that naturally controls odor, blocks UV rays, and dries 200% faster than cotton. As an OEM manufacturer, we handle the complete sourcing and production process for your brand.

Q: Does coffee fabric actually smell like coffee?

iGreen Tex Vietnam: Fresh coffee fabric has a mild natural coffee scent that fades after the first wash. Most customers find it pleasant or neutral. In our 17+ years of garment manufacturing, we’ve received positive feedback on this characteristic. The scent doesn’t affect performance or quality.

Q: Is coffee fabric genuinely sustainable, or is it just marketing?

iGreen Tex Vietnam: Coffee fabric offers real environmental benefits. We divert coffee waste from landfills, use low-energy production (160°C vs. 600°C), and reduce carbon emissions by 48%. However, we’re transparent: 95% is still recycled PET. We provide GRS certification with every order to verify our sustainability claims. As Vietnam-based manufacturers, we have direct access to local coffee waste, reducing transportation emissions.

Pricing & Commercial Terms

Q: How much does coffee fabric cost compared to regular materials?

iGreen Tex Vietnam: Coffee fabric runs 20-50% higher than conventional cotton or polyester. Current wholesale fabric pricing ranges $5-15 USD/meter depending on GSM weight and specifications. We provide detailed costing based on your specific requirements. Volume orders above 2,000 pieces unlock better fabric pricing we pass to you.

Q: What payment terms do you offer for coffee fabric orders?

iGreen Tex Vietnam: Standard terms for new clients:

- 30% deposit upon order confirmation

- 70% balance before shipment

- FOB Ho Chi Minh City or CMT terms available

For established partnerships, we discuss extended payment terms. We sign NDAs to protect your designs and business information.

Q: Can you provide samples before I commit to bulk orders?

iGreen Tex Vietnam: Absolutely. We provide:

- Fabric swatches: Free (shipping charged)

- Pre-production samples: Cost depends on complexity

- Size set samples: Available before bulk production

Sample lead time is 7-10 days. We recommend testing coffee fabric performance with your target market before placing bulk orders.

Technical Specifications & Quality

Q: What GSM weight do you recommend for different product types?

iGreen Tex Vietnam: Based on our export experience with US and European markets:

- T-shirts: 150-180 GSM for lightweight comfort

- Polo shirts: 180-200 GSM for structure

- Hoodies: 200-250 GSM for warmth

- Activewear: 160-200 GSM for performance

We adjust recommendations based on your target market climate and customer preferences. Our sampling process helps determine the optimal weight.

Q: What certifications can you provide for coffee fabric products?

iGreen Tex Vietnam: We source coffee fabric with:

- GRS (Global Recycled Standard) – Verifies recycled content

- OEKO-TEX Standard 100 – Confirms chemical safety

- Bluesign® – Environmental compliance (when specified)

All certifications include batch traceability. We provide documentation with shipments for your brand’s transparency needs and retail requirements.

Q: How do you ensure consistent quality across production runs?

iGreen Tex Vietnam: Our quality control process includes:

- Fabric inspection upon receipt (color, weight, defects)

- Pre-production sample approval before bulk cutting

- In-line quality checks during sewing

- Final inspection before packing (measurements, stitching, finishing)

- Random AQL sampling for export standards

We photograph quality checkpoints and share reports. After 17+ years in garment export, we understand international quality expectations.

Q: Can coffee fabric handle screen printing and embroidery?

iGreen Tex Vietnam: Yes. Coffee fabric works with standard decoration methods:

- Screen printing: Excellent adhesion

- Heat transfer: Test first (some films don’t adhere well)

- Embroidery: Stable for standard embroidery

- Sublimation: Possible but test required

We coordinate decoration in-house or with trusted partners. Our cut & sew facility handles complete garment production including printing and finishing.

Production Capabilities & Manufacturing

Q: What product categories can you manufacture with coffee fabric?

iGreen Tex Vietnam: We specialize in knitwear manufacturing:

- T-shirts & tank tops (crew neck, V-neck, custom styles)

- Polo shirts (pique, jersey, performance styles)

- Hoodies & sweatshirts (pullover, zip-up)

- Activewear (athletic shirts, training apparel)

- Uniforms (corporate, hospitality, retail)

Our expertise is cut & sew production for export markets. We don’t manufacture woven garments or heavy outerwear.

Q: Do you only work with coffee fabric, or can I mix materials?

iGreen Tex Vietnam: We’re flexible. Many clients combine coffee fabric with:

- Organic cotton for cost balance

- Recycled polyester for performance panels

- Bamboo fiber for premium lines

- Standard materials for trim and details

This approach manages costs while maintaining sustainability positioning. We source multiple sustainable materials beyond coffee fabric.

Q: Can you handle small production runs for new brands?

iGreen Tex Vietnam: Yes. We work with fashion startups and emerging brands. Our 1,000-2,000 piece MOQ is suitable for:

- Testing new product lines

- Launching sustainable collections

- Kickstarter or crowdfunding campaigns

- Market validation before scaling

We understand startups need flexibility. We’ve helped numerous brands grow from initial orders to regular production.

Q: What markets do you export to?

iGreen Tex Vietnam: Our primary export markets:

- United States – Largest market, familiar with FOB terms

- Europe – EU compliance experience

- Australia – Growing sustainable market

- Japan – Quality-focused buyers

Vietnam’s trade agreements provide tariff advantages for these markets. We understand export documentation and compliance requirements.

Logistics & Export

Q: What shipping terms do you offer?

iGreen Tex Vietnam: We provide:

- FOB Ho Chi Minh City (most common for export)

- CMT (Cut, Make, Trim) if you supply materials

- EXW (Ex-works) for clients with Vietnam logistics partners

We coordinate with freight forwarders and provide complete export documentation. Our location in Tan Binh District offers easy access to port facilities.

Q: How do you package garments for export?

iGreen Tex Vietnam: Standard export packaging:

- Individual polybags (biodegradable available)

- Carton packing with your specifications

- Labeling: hang tags, care labels, size labels (we produce or attach yours)

- Barcode integration if required

- Carton marking per shipping instructions

We follow your packing requirements for retail-ready shipments.

Q: Can you handle multiple shipping destinations?

iGreen Tex Vietnam: Yes. We coordinate:

- Split shipments to different warehouses

- Direct-to-retail distribution (with advance planning)

- Container consolidation with other orders