- Top 3 Must-Knows for Uniform Manufacturing in Vietnam

- Why is a Factory’s Verifiable QC System More Important Than a Perfect Sample?

- Why is Your Dedicated Project Manager More Critical Than the Newest Machinery?

- Why is a Low Price Meaningless Without Full Supply Chain Transparency?

- From Procurement Task to Strategic Advantage

- Understanding the Landscape of Uniform Manufacturing in Vietnam

- Ready to Build a Partnership?

- About iGreen Tex Vietnam

- IGREEN TEX VIETNAM CO LTD

Top 3 Must-Knows for Uniform Manufacturing in Vietnam

You’ve shortlisted potential partners for Uniform Manufacturing in Vietnam. They all present attractive pricing. But now, the real, high-stakes questions begin. How can you guarantee that piece 1,000 has the same quality as the approved sample? Who will be your eyes and ears on the factory floor, thousands of miles away? These questions are crucial for any sourcing manager navigating the world of Uniform Manufacturing in Vietnam.

These aren’t just logistical hurdles; they are critical business risks. The wrong partnership in Uniform Manufacturing in Vietnam can lead to significant budget overruns. It can cause catastrophic shipping delays. These issues might even create irreversible damage to your brand’s reputation. Finding a reliable partner is essential for your success. True success in Uniform Manufacturing in Vietnam depends on more than just a good price. It requires a deep understanding of the process.

This guide moves beyond generic advice. We will reveal three insider “must-knows”. These are the critical insights that distinguish a simple supplier from a true OEM production partner. This is your roadmap. It helps you build a resilient and reliable apparel supply chain. This is how you master Uniform Manufacturing in Vietnam. You will learn how to select the right partner for your needs.

Why is a Factory’s Verifiable QC System More Important Than a Perfect Sample?

A perfect sample proves a factory can produce one good item. They make it under ideal conditions. A verifiable Quality Control (QC) system, however, proves much more. It shows they can consistently replicate that quality across thousands of units. The system actively manages risk from raw material sourcing to final packaging. A top-tier partner in Uniform Manufacturing in Vietnam focuses on the system, not just the sample. This is the first rule for success in Uniform Manufacturing in Vietnam.

Many sourcing managers fall into a common trap. They focus too much on the sample. Any factory can concentrate its best resources to create one perfect item. But this says little about their ability to handle bulk orders. The real challenge of Uniform Manufacturing in Vietnam is consistency at scale. Mass production introduces countless variables. A great partner for Uniform Manufacturing in Vietnam controls these variables. Consistent quality over a large order is the real test of a factory’s capability. This requires a robust, documented, and verifiable process. Without a system, quality can vary wildly.

The discussion must shift from the sample to the system. You need to understand professional quality standards. For example, AQL (Acceptable Quality Limit) is a key concept. An AQL of 2.5/4.0 is a common standard in the apparel industry. It defines the maximum number of defective units acceptable in a batch. An expert in Uniform Manufacturing in Vietnam will understand and apply these standards rigorously. Their QC process should be transparent. A typical process includes multiple stages. It starts with checking incoming raw materials using a 4-point system for fabric. It continues with in-line inspections during sewing. It ends with a final inspection of finished garments. Each step is vital for quality in Uniform Manufacturing in Vietnam.

This systematic approach to quality is non-negotiable for international trade. It’s what separates domestic workshops from a professional uniform factory for Vietnam export capable of meeting global compliance standards. You should always ask a potential partner about their specific QC procedures. This is a critical step in vetting any company for Uniform Manufacturing in Vietnam. Ask them to provide documentation. This shows their commitment to quality.

In our experience, a structured QC process prevents most issues. For instance, at iGreen Tex, our five-stage quality gate system is a core part of our Uniform Manufacturing in Vietnam process. It begins with raw material verification and ends with a final AQL check before packing. This documented approach identifies potential problems early. This ensures the final shipment meets the client’s exact standards. This level of detail is a hallmark of reliable Uniform Manufacturing in Vietnam.

Why is Your Dedicated Project Manager More Critical Than the Newest Machinery?

Automated machinery only executes tasks. A skilled, English-speaking Project Manager (PM) manages complexity. They anticipate problems and serve as your single point of communication. They are the human element that ensures your design intent is flawlessly executed. A great company involved in Uniform Manufacturing in Vietnam invests in skilled people, not just machines. The PM is your most valuable asset when sourcing overseas.

Many businesses face challenges when sourcing from overseas. Working with a factory that lacks professional project management can be a nightmare. You might face serious language barriers. Email responses may be slow. You may have to contact multiple departments for a simple update. This confusion is a common frustration in global Uniform Manufacturing in Vietnam. Critical mistakes might not be reported until it is too late. This creates stress, delays, and costly errors. The quality of communication is a key indicator of professionalism.

An ideal Project Manager is your strategic partner inside the factory. They act as a cultural bridge. They are your single, reliable point of contact. They provide proactive updates, often with photos and videos. When problems arise, they solve them on the spot. They are your “boots on the ground,” giving you peace of mind. A PM from a good partner acts as an extension of your own team. They make the process of Uniform Manufacturing in Vietnam feel manageable and secure. They ensure every detail matches your specifications.

This level of hands-on management defines a true OEM uniform supplier in Vietnam. The PM translates your vision into technical instructions. They oversee timelines and manage resources effectively. Their expertise is what transforms a good factory into a great partner. Choosing a company with strong project management is crucial for success in Uniform Manufacturing in Vietnam. This factor cannot be overstated when evaluating partners.

Our approach to Uniform Manufacturing in Vietnam is human-centric. Each client at iGreen Tex is assigned a dedicated, English-fluent Project Manager. This individual is based in our Binh Duong facility. They are not just a contact; they are your advocate on the factory floor. They ensure seamless communication and execution. This direct line of command is central to our service model for Uniform Manufacturing in Vietnam. It prevents problems and builds lasting trust.

Why is a Low Price Meaningless Without Full Supply Chain Transparency?

A low final price can conceal hidden costs. These costs may relate to non-compliant materials or unethical labor practices. Full supply chain transparency ensures your price reflects true, sustainable value. It protects your brand’s reputation and guarantees product safety. A trustworthy partner for Uniform Manufacturing in Vietnam will always be transparent. This transparency is the foundation of a healthy business relationship.

The lowest price is often the most expensive choice. A cheap quote might mean the factory is cutting corners. They could be using substandard fabrics that fail safety tests. They might be ignoring labor laws. These hidden risks can lead to products being rejected at customs. This can cause negative press and damage your brand. A professional in Uniform Manufacturing in Vietnam understands that true value includes ethics and compliance. The integrity of your supply chain is paramount.

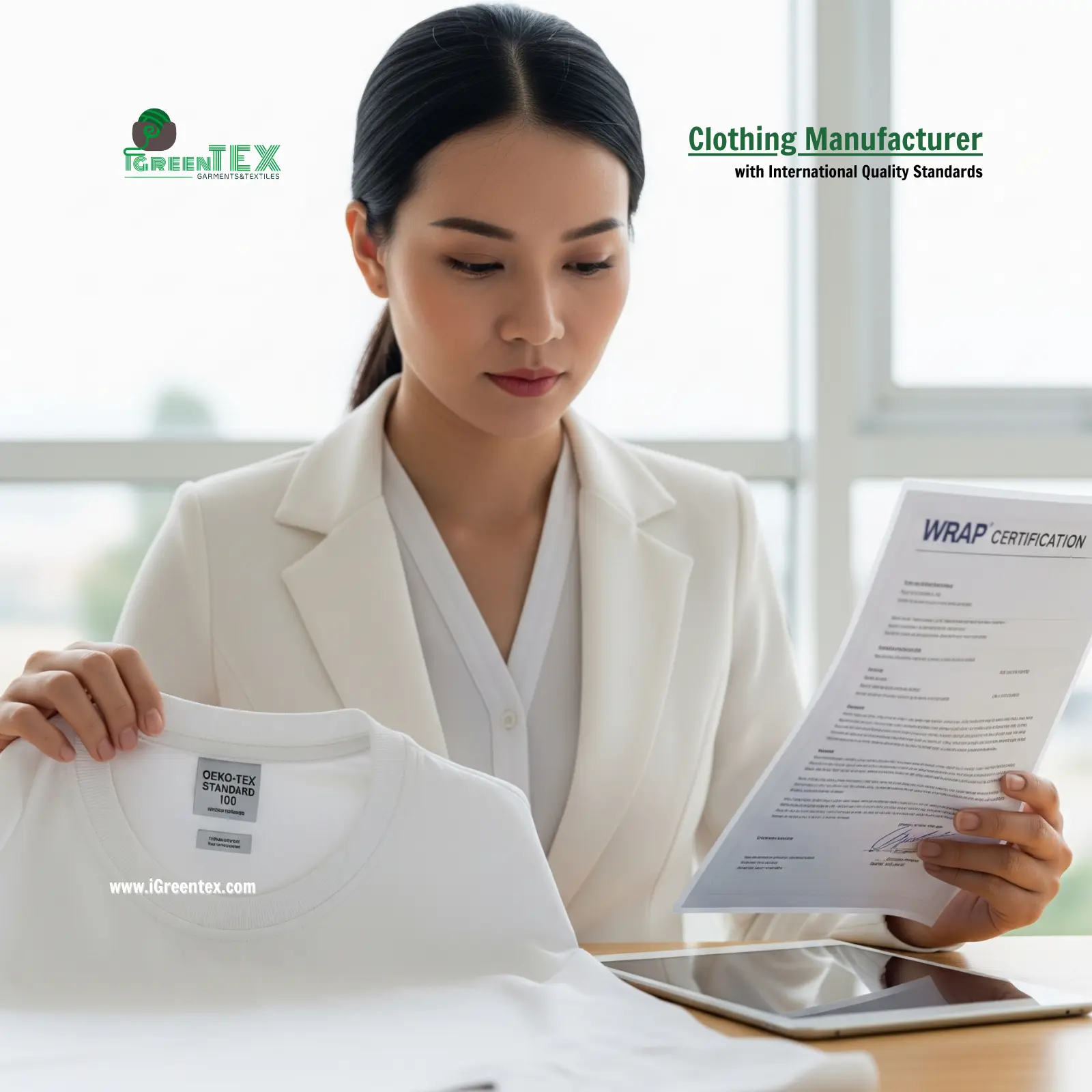

Sourcing managers in the US and EU must consider key certifications. These are a guarantee of safety and responsibility. For example, OEKO-TEX Standard 100 ensures fabrics are free from harmful substances. Social compliance audits like BSCI or WRAP ensure fair labor conditions. An ethical partner in Uniform Manufacturing in Vietnam will proudly share their certifications. Traceability is also becoming more important. Knowing your material’s origin is vital for brand integrity.

Understanding the total cost of ownership is vital, especially for large orders. A transparent partner provides clear FOB terms and a cost breakdown. This is essential when working with a bulk uniform manufacturer in Vietnam. This clarity helps you make an informed decision. Ask your potential partner about their sourcing policies. Their answers will reveal their commitment to responsible Uniform Manufacturing in Vietnam.

Transparency is non-negotiable for us. As a WRAP-certified facility, our commitment to ethical Uniform Manufacturing in Vietnam is externally audited. Our quotes detail fabric origins and certifications, so clients understand the true value they receive. This protects their brand from the risks of an opaque supply chain. This is the standard you should expect from any company offering Uniform Manufacturing in Vietnam.

From Procurement Task to Strategic Advantage

The path to sourcing uniforms successfully isn’t about finding the cheapest factory. It’s about mitigating risk by finding a true production partner. You can turn a procurement task into a powerful strategic advantage. This happens by shifting your evaluation from the sample to the system. You must look beyond the machinery to the people. You must analyze the price for its transparent value chain. A great partner for Uniform Manufacturing in Vietnam will help you make this shift.

The difference between a supplier who takes your order and a partner who protects your brand is clear. It lies in their verifiable commitment to quality systems. It depends on their proactive communication. It is proven by their ethical and transparent operations. When you find a partner that excels in these three areas, you have found a long-term asset for your business. You have mastered Uniform Manufacturing in Vietnam.

Understanding the Landscape of Uniform Manufacturing in Vietnam

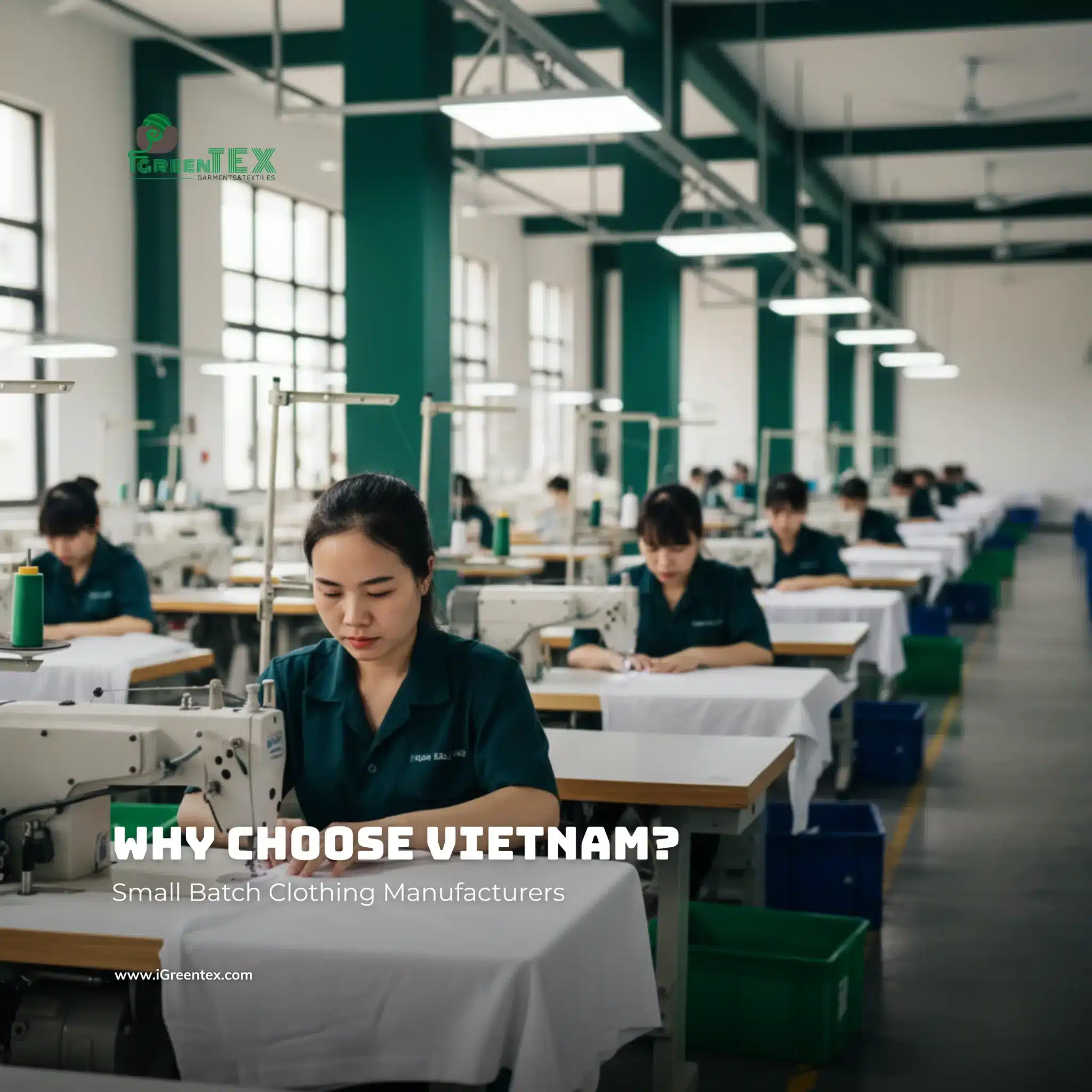

The global supply chain is constantly shifting. For decades, sourcing managers looked to a single country for their manufacturing needs. Today, the map is more diverse and strategic. At the forefront of this evolution is Vietnam. The rise of Uniform Manufacturing in Vietnam is not a fleeting trend. It is a strategic move driven by powerful economic and logistical advantages. Understanding this landscape is the first step for any sourcing manager looking to build a resilient and cost-effective supply chain for their apparel needs. This knowledge is essential for success.

So, why has Uniform Manufacturing in Vietnam become such a critical topic in boardrooms worldwide? The answer lies in a combination of factors that create a compelling value proposition. Firstly, Vietnam has strategically positioned itself as a hub for global trade. The country is a member of major free-trade agreements like the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and the EU-Vietnam Free Trade Agreement (EVFTA). For a sourcing manager in the US or EU, this translates directly into significant cost savings through reduced tariffs. This makes the final landed cost of goods produced through Uniform Manufacturing in Vietnam highly competitive.

Secondly, the nation boasts a young, dynamic, and highly skilled workforce. The textile and garment industry has a long history in Vietnam. This has cultivated a deep pool of talent with exceptional dexterity and a strong work ethic. Workers are experienced in complex sewing techniques and quality control processes. This is a crucial asset for producing high-quality, consistent apparel. The commitment to craftsmanship is a cornerstone of the burgeoning Uniform Manufacturing in Vietnam sector. This human factor is a significant advantage over more automated, but less flexible, manufacturing hubs.

Finally, the Vietnamese government has actively supported the growth of its industrial sector. This includes significant investment in infrastructure, such as modernizing seaports in Ho Chi Minh City and Hai Phong. Industrial zones are well-planned and offer a stable environment for production. This stable political and economic climate provides the predictability that international businesses require. These elements combined make Uniform Manufacturing in Vietnam a reliable and forward-thinking choice. It is a strategic decision, not just a procurement one.

However, not all factories are created equal. Navigating the landscape of Uniform Manufacturing in Vietnam requires understanding the different tiers of suppliers. At the top, you have massive, vertically integrated conglomerates. They often own their own spinning, weaving, and dyeing facilities. While impressive, they typically demand massive order quantities (MOQs) and are better suited for fast-fashion giants. Their production lines are less flexible for the specialized needs of uniform programs.

The sweet spot for most international brands lies in the second tier: mid-sized, specialized OEM/ODM partners. These factories are the backbone of the Uniform Manufacturing in Vietnam industry. They focus on specific product categories, like corporate wear, workwear, or school uniforms. Their strength lies in their flexibility, expertise, and client-centric service models. They often have strong project management teams and a deep understanding of export requirements. They offer a perfect balance of quality, cost, and service for most uniform sourcing needs. This is where true partnerships are built.

At the bottom are countless small workshops and subcontractors. While they may offer tempting low prices, they present significant risks. These can include inconsistent quality, poor communication, and a lack of compliance with international labor and safety standards. For any serious brand, these risks far outweigh the potential cost savings. A successful strategy for Uniform Manufacturing in Vietnam involves identifying and partnering with the reliable second-tier suppliers.

Despite the many advantages, sourcing managers must also be aware of potential challenges. One key consideration in Uniform Manufacturing in Vietnam is raw material sourcing. While the country is strong in cut-and-sew operations, it still relies on importing a significant portion of its high-tech and specialized fabrics. A top-tier manufacturing partner mitigates this by having strong, long-standing relationships with reputable fabric mills across Asia. They manage these supply chains proactively, ensuring that lead times and quality are not compromised.

Another challenge is navigating cultural and communication differences. This is perhaps the most underestimated risk in global sourcing. This is why the human element is so critical. A successful engagement in Uniform Manufacturing in Vietnam often depends on the quality of your partner’s communication. This reinforces the importance of working with factories that provide dedicated, English-speaking project managers who can act as your seamless bridge to the production floor.

In conclusion, Vietnam offers a powerful and strategic platform for apparel sourcing. Its blend of favorable trade agreements, skilled labor, and a stable industrial environment has cemented its position as a global leader. The success of your Uniform Manufacturing in Vietnam initiative will hinge on your ability to look beyond the price tag. It requires you to understand the different tiers of suppliers and to choose a partner who offers transparency, strong project management, and a verifiable commitment to quality. By doing so, you are not just buying a product; you are building a resilient, ethical, and valuable extension of your own business.

Ready to Build a Partnership?

Ready to build a partnership, not just place an order? Schedule a free, no-obligation consultation with our manufacturing experts. Let’s discuss your project. We can show you how our approach to Uniform Manufacturing in Vietnam can bring your vision to life. Let us help you source with confidence and transparency.

About iGreen Tex Vietnam

iGreen Tex Vietnam is a trusted fashion and textile manufacturer based in Vietnam, specializing in high-quality sportswear and casual apparel for global markets. We provide OEM manufacturing services, supporting brands to design, develop, and produce customized garments that meet international quality standards.

Our production focuses on sustainability and eco-friendly practices, using certified fabrics and advanced techniques to reduce environmental impact. From material sourcing to final inspection, every stage of manufacturing follows strict quality control processes to ensure flawless results. With years of experience in Vietnam sportswear manufacturing, we understand the demands of global clients and changing fashion trends.

Our factory operates with modern equipment and a dedicated team to deliver products on time and at competitive pricing. Partnering with iGreen Tex means working with a reliable supplier who combines innovation, quality, and responsibility. We help your brand scale effectively by producing garments that resonate with today’s conscious consumers worldwide.

If you want to read more information about canvas bags, and if you want to tote bags at Ho Chi Minh City, you can see it here!!!

To view product information click here

Visit our website to learn more about our products and services: IGREEN TEX

IGREEN TEX VIETNAM CO LTD

Address: No. 6 – 6A, D52 Street, Bay Hien Ward, Ho Chi Minh City, Vietnam

E-mail: Info@iGreentex.com

WhatsApp/Viber/Zalo: +84 (0) 938.045.900