- Why You Are Not Ready to Contact Garment Manufacturer Yet (And Why That Is Okay)

- The Hesitation form the Contact Page, Right?

- Reason 1: The Fear of Minimum Order Quantity (MOQ)

- Reason 2: You Do Not Have a “Tech Pack” Yet

- Reason 3: You Want to Verify the Factory First

- Reason 4: You Are Not the “Boss” (Role Anxiety)

- Reason 5: Fear of Spam and Sales Pressure

- Reason 6: Your Project Timeline is Too Far Out

- What Happens When You ARE Ready?

- The Advantage of Vietnamese Manufacturing

- Summary: It Is Okay to Wait, But Do Not Wait Too Long

- Frequently Asked Questions (FAQ)

- Final Thoughts for the Buyer

Why You Are Not Ready to Contact Garment Manufacturer Yet (And Why That Is Okay)

The Hesitation form the Contact Page, Right?

You have navigated to the iGreen Tex contact page. You have read about our Vietnam-based OEM services. You see the form. However, you do not fill it out. You close the tab or save it for later.

This is a very common scenario in the b2b apparel sourcing process.

If you feel you are not ready to contact garment manufacturer iGreen Tex, it is usually a sign of a professional mindset. You are cautious. You want to be prepared. In the B2B world, research is just as important as the transaction. At iGreen Tex, we source our own raw materials, so we understand this behavior. We also hesitate until we are sure about a supplier.

This article analyzes why you might feel not ready to contact garment manufacturer iGreen Tex today. We will explain our specific policies on MOQ, Tech Packs, and factory visits. We aim to help you understand when to contact a garment factory like ours. We want you to feel confident, not pressured.

Reason 1: The Fear of Minimum Order Quantity (MOQ)

The most common reason buyers are not ready to contact garment manufacturer iGreen Tex is the volume requirement. You see “1,000 pieces” and you worry.

Perhaps you are a startup. Perhaps you are testing a new market. You might think, “I cannot sell 1,000 items of one single shirt.”

The Reality of iGreen Tex MOQ

We need to clarify this policy. We state an MOQ of 1,000 pieces. However, this is not as rigid as you think.

We understand that ordering 1,000 pieces per style is difficult for many brands. It is a high risk for inventory. Therefore, iGreen Tex offers flexibility.

Our Flexibility Policy:

We accept an order of 1,000 pieces total. Within this 1,000 pieces, you can mix different styles. You do not need to order 1,000 of the exact same T-shirt. You can combine items to reach the total volume.

This allows us to run our production lines efficiently while helping you manage stock. As long as the total production run hits 1,000 units, we are happy to work with you.

The Exception: Custom Dyeing

There is one exception to this flexibility. This applies if you need specific fabric colors dyed to a custom Pantone code.

If you are not ready to contact garment manufacturer because of color requirements, you need to know technical facts. Dyeing machines require a minimum weight of fabric to operate correctly. If the fabric volume is too low, the machine cannot maintain consistent color. The chemical ratio will be incorrect.

Therefore, for custom colors, the MOQ might be higher or stricter. This is not a business rule. It is a technical limitation of industrial dyeing machinery.

MOQ Comparison Table

| Order Type | MOQ Requirement | Flexibility | Reason |

| Standard Fabric Colors | 1,000 Pieces Total | High. Can mix multiple styles/designs. | We use available fabric stock. |

| Custom Dye (Pantone) | > 1,000 Pieces (Depends on fabric weight) | Low. Must meet dyeing machine capacity. | Technical requirement for color consistency. |

| Print/Embroidery | Included in 1,000 Total | High. Can vary designs. | Printing setup is flexible. |

Reason 2: You Do Not Have a “Tech Pack” Yet

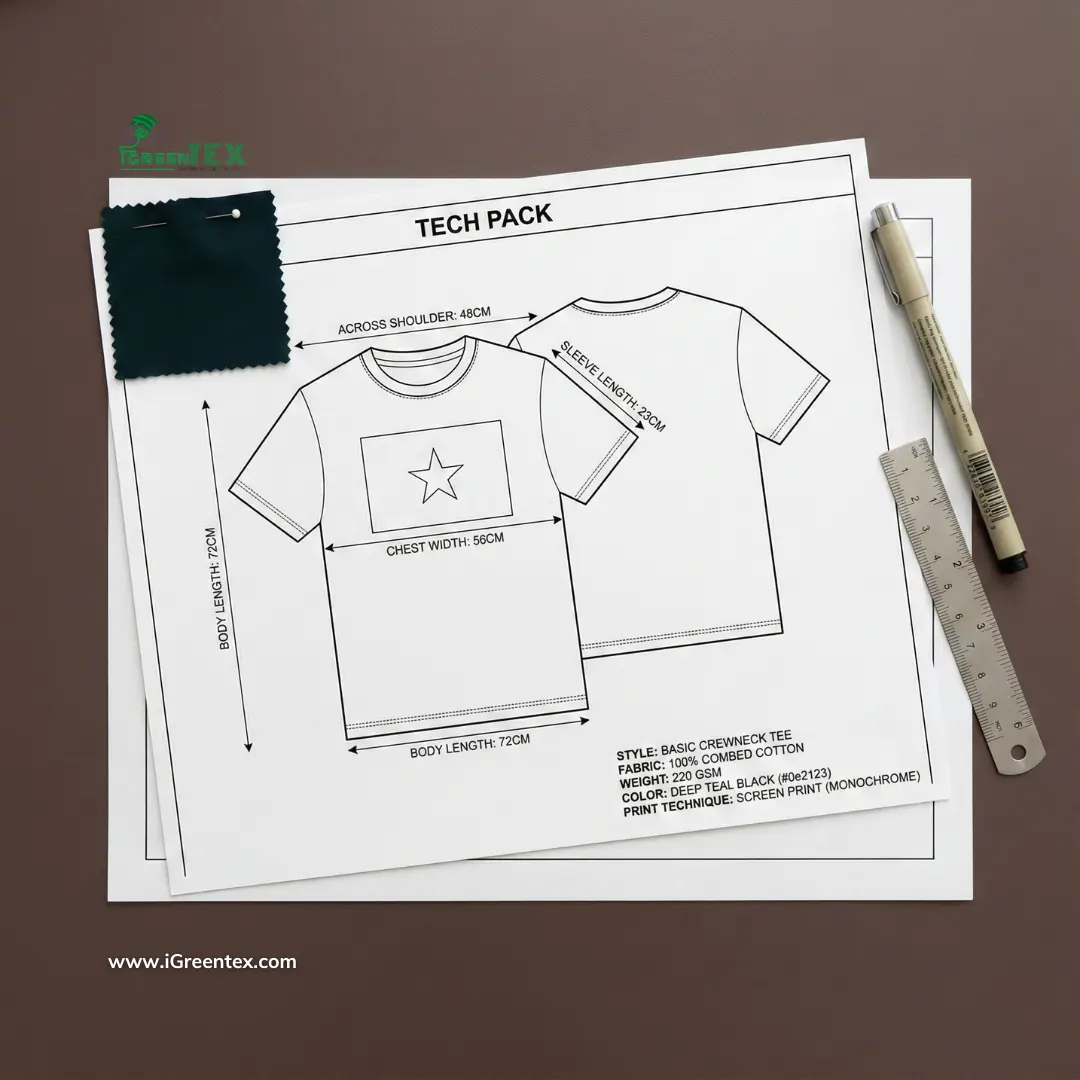

This is the second biggest reason why clients are not ready to contact garment manufacturer iGreen Tex. You have a sketch. You have a photo from Pinterest. But you do not have a Tech Pack.

You might be afraid that we will reject you. Or, you might hope that a photo is enough.

The “No Tech Pack, No Quote” Policy

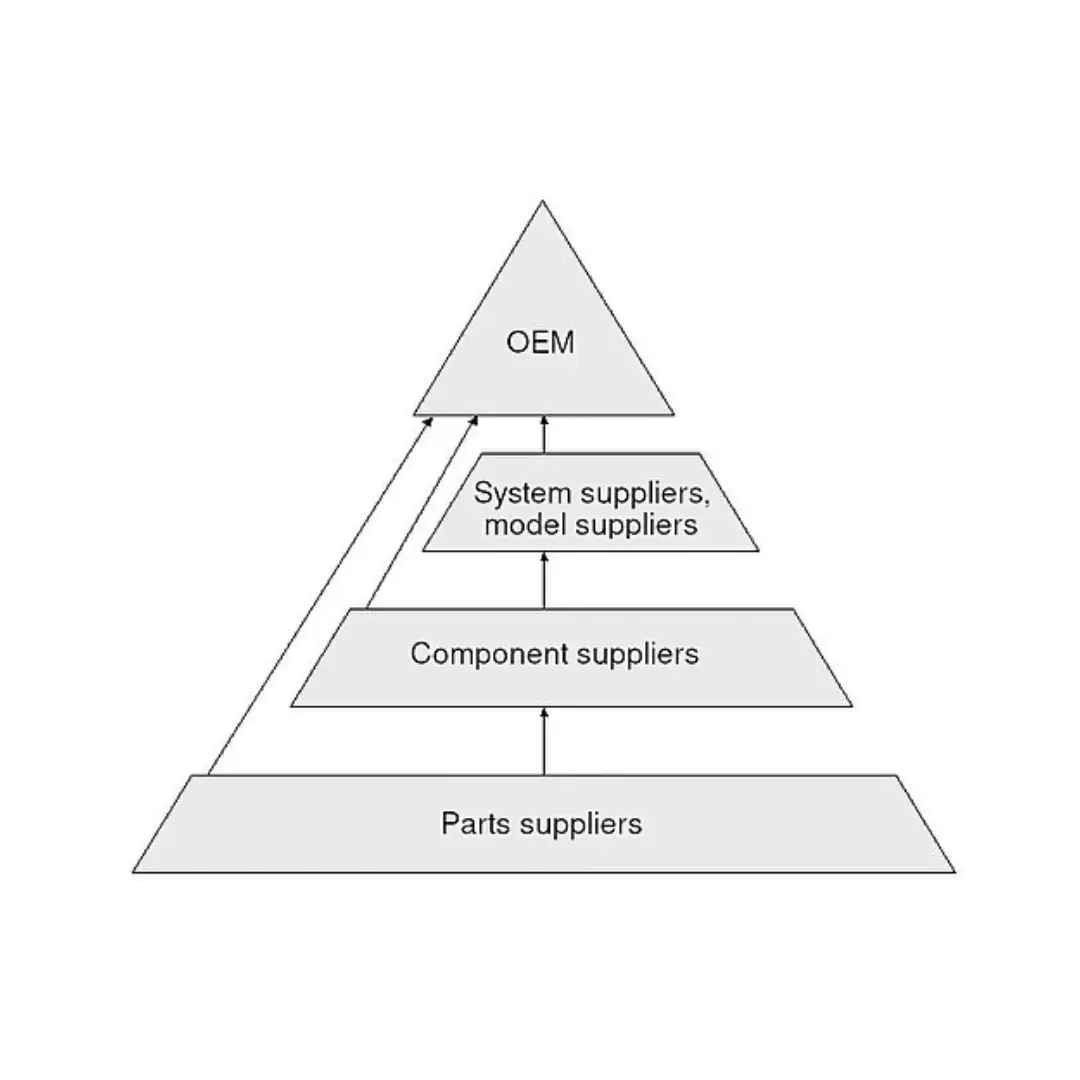

At iGreen Tex, we follow a strict OEM (Original Equipment Manufacturer) model. We must be honest with you. We do not accept orders based only on images.

If you send us a photo of a hoodie and ask, “Can you make this?”, we will say no. Or we will ask for the Tech Pack.

Why are we so strict?

- Price Accuracy: We cannot calculate fabric consumption from a photo. Without consumption data, we cannot give you a price.

- Risk of Error: A photo does not show the fabric weight (GSM). It does not show the stitching method. It does not show the size grading.

- Vietnamese Market Reality: Many factories in Vietnam will say “Yes” to a photo. They will guess the details. Then, they will produce a wrong sample. You will lose money and time.

We refuse to let you lose money. We protect our clients by demanding a Tech Pack. This document acts as a contract of specifications. It ensures we speak the same language. See more about us!

Is a “Preliminary” Tech Pack Enough?

Some clients ask if a rough draft is okay. They feel not ready to contact garment manufacturer with a full document.

At iGreen Tex, we require a Full Tech Pack to start the official quotation and sampling process. A preliminary pack makes it hard to estimate costs. We want to give you a final, accurate price immediately. We do not want to change the price later because the details changed.

If you are not ready to contact garment manufacturer because you lack this document, take time to hire a freelance technical designer. It is a small investment that saves thousands of dollars in production errors.

What We Need in a Tech Pack

- Bill of Materials (BOM): List of all fabrics, buttons, zippers, and threads.

- Measurement Chart: Size specs for S, M, L, XL, etc.

- Grading Rules: How much the size changes between S and M.

- Construction Details: Stitch types (lockstitch, coverstitch, etc.).

- Artwork Files: Vector files for logos or prints.

Reason 3: You Want to Verify the Factory First

Trust is the currency of international trade. You are sitting in the USA, Europe, or Australia. We are in Vietnam. You are not ready to contact garment manufacturer iGreen Tex until you know we are real.

You might be looking at our office photos. You might be checking our address. This is a very smart part of the b2b apparel sourcing process.

Factory Visits and Transparency

We encourage visits. We are proud of our facility. We openly display images of our office and factory. We want you to see our cutting machines, our sewing lines, and our QC area.

However, we have a specific protocol for visits.

The 3-Day Notice Rule

If you want to visit iGreen Tex, you must book an appointment at least 03 days in advance. So, booking now!

We are a busy manufacturing facility. We have strict production schedules. We also host many international clients. 90% of our visitors are from overseas (USA, EU, Japan). Only 10% are domestic.

If you show up without notice, we cannot welcome you properly. We might be in a meeting with another client. We want to respect your time. By booking 3 days ahead, we can prepare samples relevant to your needs. We can ensure the right manager is available to speak with you.

If you are not ready to contact garment manufacturer iGreen Tex because you cannot visit yet, that is fine. You can schedule a video call tour first. But when you come to Vietnam, please remember the 3-day rule. It ensures a professional experience.

Reason 4: You Are Not the “Boss” (Role Anxiety)

Sometimes, the person viewing our website is not the CEO. You might be a Junior Sourcing Assistant. You might be a Product Developer.

You might feel not ready to contact garment manufacturer because you are not the final decision-maker. You worry that we only want to talk to the Founder.

We Treat Every Contact Equally

This anxiety is unnecessary at iGreen Tex. We understand corporate structures. We know that the Founder often does not have time to source fabrics. That is your job.

Whether you are a Brand Owner, a Sourcing Manager, or an Assistant, we treat you with the same respect. We process your inquiry with the same speed.

What Matters to Us:

- Do you have the Tech Pack?

- Do you meet the MOQ (1,000 mixed)?

- Are you serious about production?

If the answer is yes, we work with you. In fact, we often prefer working with Product Developers because they understand the technical details better than the Founders. You are the bridge. We support you so you can present the best options to your manager.

Do not feel not ready to contact garment manufacturer iGreen Tex just because of your job title. If you have the data, you have the power.

Reason 5: Fear of Spam and Sales Pressure

You fill out a form. Suddenly, your phone rings five times a day. Your inbox fills with “Just checking in!” emails.

This is a nightmare. It is a major reason why buyers are not ready to contact garment manufacturer forms. You want information, not harassment.

iGreen Tex Communication Protocol

We are an industrial manufacturer, not a marketing agency. We do not have a team of aggressive salespeople trying to hit a daily call quota.

- No Spam: We use your email and phone number for work purposes only.

- Privacy: Your designs and contact info are confidential.

- Channel Preference: We communicate via Email or WhatsApp, depending on what you prefer.

- Relevance: We only contact you regarding your specific project or query.

When you contact us, the person replying is usually from the Order Receiving Department or a Merchandiser. They are focused on technical feasibility and pricing. They are not focused on “closing the deal” at all costs.

If you are not ready to contact garment manufacturer iGreen Tex because of spam fear, you can relax. We are too busy making clothes to spam you.

Reason 6: Your Project Timeline is Too Far Out

You might be planning for a collection that launches in one year. You think it is too early. You think you are not ready to contact garment manufacturer iGreen Tex until next season.

Understanding Lead Times

In the b2b apparel sourcing process, “early” is actually “on time.”

Manufacturing is slow. It is physical. It involves shipping raw materials, lab dips, sampling, corrections, production, and ocean freight.

Average Timeline at iGreen Tex:

- Discussion & Quoting: 1-2 Weeks.

- Sampling & Adjustments: 3-4 Weeks.

- Material Sourcing: 2-4 Weeks.

- Bulk Production: 4-8 Weeks.

- Shipping (Sea Freight): 4-6 Weeks.

Total time can range from 3 to 6 months. For large or complex orders, it can take up to 1 year.

If you are researching now for a launch in 6 months, you are contacting us at the perfect time. Do not wait. If you wait until you are “ready” (1 month before launch), it will be too late.

We have data showing that 70% of our new clients who plan early end up reordering. Those who rush usually face stress and higher costs.

Timeline Planning Table

| Phase | Duration | What Happens |

| Contact & Quote | 1-2 Weeks | You send Tech Pack. We give price. |

| Sample Dev | 2-4 Weeks | We make a prototype. You check fit. |

| PO & Deposit | 1 Week | Contract signed. Fabric booked. |

| Production | 4-8 Weeks | Cutting, Sewing, QC, Packing. |

| Logistics | 3-6 Weeks | Transport to Port (Cat Lai) -> Your Country. |

If your project is 6 months away, you are not ready to contact garment manufacturer later. You are ready now.

What Happens When You ARE Ready?

Now that we have addressed why you are not ready to contact garment manufacturer iGreen Tex, let’s look at the next steps. What happens when you finally click “Send”?

Understanding the workflow removes the fear. Here is the b2b apparel sourcing process with iGreen Tex.

Step 1: Submission and Review

You send us your Tech Pack and quantity details via the contact form or email. Our team reviews it. We check if it fits our capabilities (e.g., is it a T-shirt, Polo, Hoodie? Is it 1,000 pieces?).

Step 2: The Quotation

We calculate the fabric consumption. We check the current yarn prices. We send you an estimated FOB (Free On Board) price. This usually happens within 3-5 business days.

Step 3: Sampling

If you agree to the price, we move to sampling. You pay a sampling fee (usually 2-3 times the FOB price, refundable on bulk). We make the first physical sample.

Step 4: Production

Once the sample is approved, you place the bulk order.

It is a structured, logical path. There are no surprises.

The Advantage of Vietnamese Manufacturing

When considering when to contact a garment factory, consider the location. iGreen Tex is located in Vietnam. This offers specific strategic advantages.

- Stable Political Environment: Vietnam is safe and stable for business.

- Logistics: We are near Cat Lai Port and Tan Son Nhat Airport. Shipping to the US and EU is established and reliable.

- Free Trade Agreements (FTAs): Vietnam has FTAs with the EU (EVFTA), UK (UKVFTA), and is part of CPTPP (Australia, Canada, etc.). This often means lower import taxes for you.

- Quality vs. Cost: Vietnam offers a higher quality of sewing than many cheaper competitors, but at a more competitive price than China.

By choosing iGreen Tex, you are accessing these national advantages.

Summary: It Is Okay to Wait, But Do Not Wait Too Long

We wrote this article to validate your feelings. It is perfectly normal to feel not ready to contact garment manufactureriGreen Tex.

- You are researching.

- You are finalizing your Tech Pack.

- You are calculating your 1,000-piece mix.

- You are planning your trip to Vietnam.

These are good signs. They show you are a serious B2B buyer.

However, do not let fear stop you.

- Fear of MOQ: Remember, we allow mixed styles.

- Fear of Titles: We respect all staff levels.

- Fear of Spam: We only talk business.

When to contact a garment factory like iGreen Tex?

Contact us when you have your Tech Pack and a target quantity of 1,000 pieces.

If you have those two things, you are ready. The rest (visiting, shipping, contracts) we can solve together.

We are iGreen Tex. We are a professional OEM factory in Vietnam. We do not need you to be ready today. But when you are, we will be here to produce high-quality garments for your brand.

Frequently Asked Questions (FAQ)

Q1: Can I contact you if I only have a sketch?

A: We strongly advise getting a Tech Pack first. We cannot provide an accurate quote based on a sketch. It protects you from pricing errors.

Q2: I want 500 T-shirts and 500 Hoodies. Does this meet the MOQ?

A: Yes. As long as the total order is 1,000 pieces, we can usually accommodate a mix of styles (excluding custom dye requirements).

Q3: Can I visit the factory next Monday?

A: Only if you book 3 days in advance. Please contact us now to schedule it. We need time to prepare for your visit.

Q4: Do you offer design services?

A: No, we are an OEM factory. We manufacture based on your designs and Tech Packs.

Q5: What is the best way to contact iGreen Tex?

A: Use the contact form on our website or email us directly. If you prefer WhatsApp for quick updates later, we can arrange that.

Final Thoughts for the Buyer

If you are still reading, you are likely part of the 90% of international buyers who are diligent and careful. We appreciate that.

Take your time. Finish your Tech Pack. verify your volume. When you cross the line from not ready to contact garment manufacturer to “Ready,” iGreen Tex will be your reliable partner in Vietnam.

We look forward to receiving your Tech Pack when the time is right.