- The Definitive Guide to Remote Clothing Quality Control for US Buyers in Vietnam

- Why remote-first QC is the new standard for US buyers in Vietnam

- What remote QC covers vs traditional 3rd-party inspections

- The proactive 3-layer QC framework in Vietnam (overview)

- Technology enablement: AI/IoT + 360° video for remote QC

- Model comparison: Sourcing agent vs direct factory in vietnam

- A practical 7–14 day checklist to start

- KPIs, SLAs, and ROI

- Risks and mitigations

- Frequently Asked Questions (FAQ)

- Aligning with search intent and next steps

- Your 30–60–90 day rollout plan

- The role of a Vietnam-based QC partner

- Conclusion and your next step

- About iGreen Tex Vietnam

- IGREEN TEX VIETNAM CO LTD

The Definitive Guide to Remote Clothing Quality Control for US Buyers in Vietnam

Why remote-first QC is the new standard for US buyers in Vietnam

The global apparel supply chain has changed permanently. After recent disruptions, US brands face new realities. Travel budgets are much tighter. Lead time pressures are more intense than ever before. The old model of flying to Vietnam for a final inspection is no longer efficient or sustainable. A new approach is now the standard for success. This approach is built on proactive, remote quality management. It focuses on preventing defects early, not just finding them later. This guide is your complete playbook for Remote Clothing Quality Control for US Buyers in Vietnam.

This major shift requires a new mindset for brand survival. Sourcing Directors and Production Managers now demand digital proof of quality. They need clear Key Performance Indicators (KPIs). They rely on verifiable Service Level Agreements (SLAs). The goal is to build a system of trust that is based on evidence. The benefits are significant. A strong remote QC program reduces defects and returns. It accelerates the sample approval process. It also optimizes your Total Cost of Ownership (TCO). This is the new benchmark for professional Virtual clothing quality assurance for American buyers.

Ready to build a more resilient supply chain?

What remote QC covers vs traditional 3rd-party inspections

It is critical to understand what a professional system for Remote Clothing Quality Control for US Buyers truly entails. It is much more than a simple video call. A robust remote QC program has two distinct goals. The first goal is to confirm that products meet your specifications. This is often measured using a statistical standard like AQL (Acceptable Quality Limit). The second, more important goal is to prevent defects from recurring. This is achieved through a structured process of Root Cause Analysis (RCA) and a Corrective/Preventive Action Report (CPAR).

This modern approach often uses a hybrid model based on risk. For a new factory or a complex product, some on-site presence is essential. For trusted, long-term partners, a fully remote process may be sufficient. This flexibility is key to successful Virtual clothing quality assurance for American buyers. The effectiveness of this system is not based on feelings. It is measured with clear data.

Key metrics include Defects per Hundred Units (DHU). Other metrics are First Pass Yield (FPY) and On-time Final Approval. You must also track the Cost of Poor Quality (COPQ). This data-driven methodology is what makes Remote Clothing Quality Control for US Buyers in Vietnam a reliable system. It truly defines successful Remote garment quality inspection for US importers.

The proactive 3-layer QC framework in Vietnam (overview)

To achieve real control, you need a structured system. We have developed a 3-Layer Proactive QC Framework. This system is designed for the realities of manufacturing in Vietnam. It provides a reliable structure for Virtual clothing quality assurance for American buyers. This framework is the core of an effective quality program.

- Layer 1: The “Ready-for-QC” Tech Pack. Quality begins with clear specifications. Your technical documents must be detailed, measurable, and unambiguous. This is the foundation of the entire process.

- Layer 2: Verifiable Virtual Inspections. This involves a structured process for inline and final inspections. It uses clear digital evidence that cannot be faked or misinterpreted.

- Layer 3: Systematic Defect Handling. When defects occur, you need a reliable process. This includes root cause analysis and implementing corrective actions with proper oversight.

This framework is designed to connect your existing systems. It links your Product Lifecycle Management (PLM) or ERP platform directly to the factory floor. It creates a seamless and transparent flow of information. This integration ensures data consistency from design to final shipment. This is the foundation of successful Remote Clothing Quality Control for US Buyers in Vietnam.

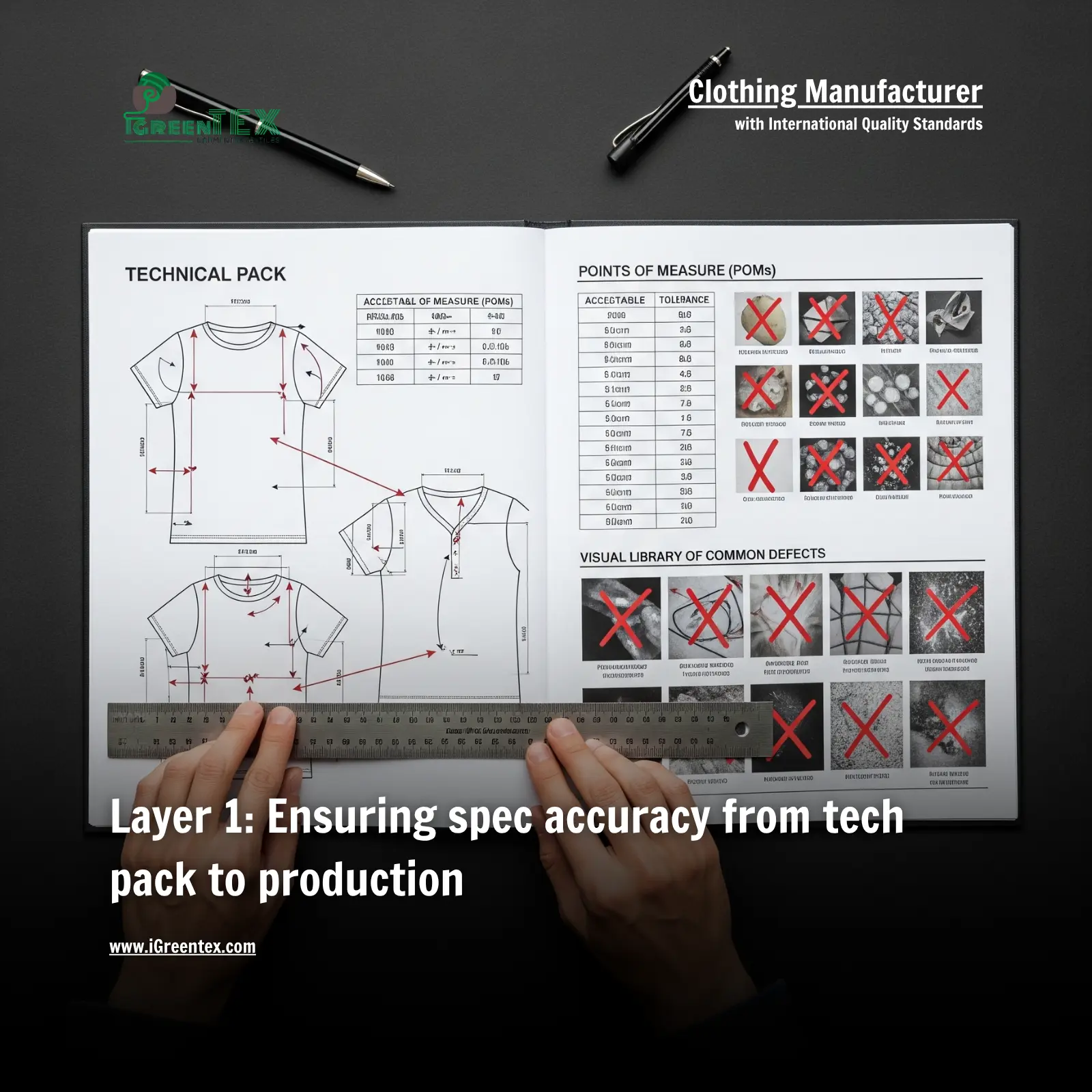

Layer 1: Ensuring spec accuracy from tech pack to production

Quality control is impossible without a clear standard to measure against. That standard is your tech pack. However, it must be “Ready-for-QC” to be effective. The entire goal of this first layer is ensuring spec accuracy from tech pack to production. A vague tech pack is the primary source of quality issues.

A Ready-for-QC tech pack must include mandatory components. It needs critical Points of Measure (POMs). It must have clear diagrams showing how to measure each point. For example, specify “chest width 1 inch below armhole.” It must also define the acceptable tolerance for each measurement. This tolerance changes for different fabrics. A knit t-shirt has more stretch and a larger tolerance than a woven shirt. The tech pack should also include a visual library of common defects. This shows the factory what is unacceptable. Examples include broken stitches, open seams, and oil stains.

The tech pack must also define acceptance criteria. This covers workmanship, trims, accessories, labeling, and packaging. These details must meet US import standards. A professional tech pack requires a system for managing changes. This includes a change log and version control. This prevents factories from using outdated specifications. This is a critical step in professional Remote Clothing Quality Control for US Buyers in Vietnam.

Layer 2: Virtual inspections with measurable outcomes

With a clear tech pack, you can now conduct inspections. These inspections must provide real, verifiable evidence. The Virtual clothing inspection process has two main stages. These stages work together to protect your quality standards. This process is essential for any modern program of Remote garment quality inspection for US importers.

The first stage is an inline inspection. This typically happens when 5–10% of the order is complete. It includes a live video call to confirm that critical POMs are correct. Your QC partner also checks high-risk raw materials. This includes fabric shade bands and trim quality. A 360-degree video of a product on a mannequin confirms the overall fit. The second stage is the final inspection. This follows a statistical AQL plan for softlines. A common standard is Major 2.5 and Minor 4.0. This can be adjusted based on your brand’s risk tolerance.

The key to success is verifiable digital evidence. This includes high-definition, close-up photos of stitching. It requires 360-degree videos with good lighting. It includes clear annotations on images to point out issues. Reports must be time-stamped. A quality partner will provide a KPI dashboard for each order. This allows you to track defect types using a Pareto chart. This level of detail makes Virtual clothing quality assurance for American buyers a reliable process.

Layer 3: Root cause and preventive control from a distance

Even with good planning, defects can still happen. How you handle them defines your long-term success. A systematic approach to Handling production defects remotely is essential for continuous quality improvement. Without this layer, you will see the same problems order after order.

The process has three simple but powerful steps. First, isolate the affected products. This action contains the problem. It prevents defective units from being packed and shipped. Second, perform a Root Cause Analysis (RCA). Simple tools like the “5 Whys” method are very effective. You repeatedly ask “Why?” to uncover the true source of the problem. A Fishbone diagram is another useful tool. Third, implement a Corrective and Preventive Action Report (CPAR). This document details the plan to fix the immediate issue. It also includes steps to prevent it from happening again.

We recommend clear SLAs for this process. A preliminary defect report should be delivered within 24 hours. A full RCA should be completed in 48–72 hours. A CPAR for major issues should be finalized within 3–5 business days. You must then validate that the CPAR was effective. This is done by tracking DHU and FPY on future orders. This is a core part of any professional Remote Clothing Quality Control for US Buyers in Vietnam.

Technology enablement: AI/IoT + 360° video for remote QC

Technology is making Remote Clothing Quality Control for US Buyers in Vietnam more powerful and data-driven. AI-powered computer vision can now assist inspectors. It can automatically flag potential issues like wrinkles, stains, or uneven seams. This serves as a “co-pilot” for the human QC professional to review. 360-degree video platforms with annotation tools allow your team to approve samples faster. This creates clear digital evidence that everyone can agree on. This technology strengthens your program for Virtual clothing quality assurance for American buyers.

For sensitive fabrics, Internet of Things (IoT) sensors are useful. They can monitor temperature and humidity in the factory. This helps prevent material damage from poor storage conditions. Integrating your QC platform with your PLM or ERP system is a major advantage. It reduces manual data entry. It ensures everyone is working from a single source of truth. For example, tech pack data from your PLM can automatically populate the QC checklist. However, it is important to understand the limits. AI is an assistant, not a replacement. The final quality decision still rests with a skilled human.

Model comparison: Sourcing agent vs direct factory in vietnam

US buyers have several options for managing production in Vietnam. Let’s compare the common models of sourcing agent vs direct factory in vietnam. This decision directly impacts the success of your entire system for Remote Clothing Quality Control for US Buyers in Vietnam.

Working directly with a factory can offer speed in pricing. It also provides a direct line for negotiations. However, if a quality issue occurs, you lack an objective third party. Getting a deep and honest root cause analysis can be very difficult. The factory may become defensive. Communication across time zones can also be slow and frustrating. These significant challenges make achieving true Virtual clothing quality assurance for American buyers very difficult when working directly. This makes direct management a challenge for Remote garment quality inspection for US importers.

A sourcing agent can help with language barriers and basic coordination. They can expand your sourcing options. However, they are often just a middleman. They may not have deep control over the factory’s internal quality processes. This is a major risk for any Remote garment quality inspection for US importers. They may be unable to enforce a CPAR at the production-line level.

The most effective model is a Vietnam-based quality management partner. They are your dedicated team. They provide objective RCA and CPAR reports. They supervise corrective actions on the factory floor, ensuring your program for Virtual clothing quality assurance for American buyers is effective. This model provides the best results for Remote Clothing Quality Control for US Buyers in Vietnam.

Mini case: Reduce DHU by ~30% without flying onsite

Here is a real-world example of this framework in action. A US brand was producing a 12,000-piece order of men’s knit t-shirts. A remote inline inspection found a critical shoulder measurement issue. It was off by +1.5 cm on sizes M and L.

- Action – Isolate: The on-site partner immediately stopped the affected sewing line. They isolated all units from that line for the two affected sizes.

- Action – RCA: The root cause was an incorrect machine setup. The pressure foot and feed dog were misaligned after a needle change. A gap in operator training was a contributing factor.

- Action – CPAR: A corrective action plan was implemented within 48 hours. The machine setup process was standardized with visual guides. A quick 30-minute training was given to the operators. 100% of the affected units were re-measured and corrected.

The results were dramatic. The DHU for this major defect dropped from 8.2 to 2.1. This was a 74% reduction. The overall First Pass Yield (FPY) for the order increased from 86% to 95%. The shipment’s ETD was not delayed. The brand saved an estimated $3,500 by not needing an emergency flight. This case shows how a structured system for Remote garment quality inspection for US importers delivers a tangible ROI.

See the Framework in Action

The same process that saved our client thousands can be applied to your products. Schedule a brief, no-obligation demo. We will show you how we can build a virtual QC process for your brand.

A practical 7–14 day checklist to start

You can start implementing this framework quickly. Here is a Remote apparel inspection checklist to guide your initial steps. This checklist helps you begin building a better process today.

Phase 1: Inline Inspection Steps (at 5-10% of production)

| Action Step | Explanation: Why This Is Critical |

| Finalize critical POMs and measurement methods. | This creates a single source of truth. It prevents arguments about how to measure, which is a common source of error and defects. |

| Approve physical shade bands, trims, and accessories. | This confirms that the correct materials are being used before they are attached to thousands of garments. It prevents massive, costly rework. |

| Request a live video call to measure 3-5 critical POMs. | This provides real-time, uneditable proof that the factory understands your specs. It confirms that production is on the right track. |

| Require a 360-degree video of a sample on a mannequin. | This helps you evaluate the overall fit, drape, and silhouette of the garment. A flat photo on a table cannot capture this essential information. |

| Get close-up, high-definition photos of stitching. | This allows you to inspect workmanship details like stitching density and cleanliness. These are key indicators of the factory’s skill and attention to detail. |

Phase 2: Final Inspection Steps (AQL)

| Action Step | Explanation: Why This Is Critical |

| Define your AQL level (e.g., Major 2.5, Minor 4.0). | This sets a clear, mathematical standard for what is acceptable. It removes subjective opinions from the final pass/fail decision. |

| Confirm the random sampling plan before the inspection. | This ensures the inspection is statistically valid. It prevents the factory from only showing you the best units they produced. |

| Verify all packaging, labeling, and UPC codes are 100% correct. | Errors here are very costly. Incorrect labels or barcodes can lead to chargebacks from retailers or major issues at the US customs border. |

Phase 3: Reporting and Data Storage

| Action Step | Explanation: Why This Is Critical |

| Use a standardized template for all photo and video reports. | This makes reports easy to compare over time and across different suppliers. It ensures no critical information is missed. |

| Ensure all media is time-stamped and mapped to a PO/lot/size. | This creates a verifiable audit trail. It links every piece of evidence to a specific order, preventing confusion and disputes. |

| Store all reports in a shared cloud folder for easy access. | This provides a centralized, accessible history of a factory’s performance. It is essential for future planning and building supplier scorecards. |

KPIs, SLAs, and ROI

To manage Remote Clothing Quality Control for US Buyers in Vietnam effectively, you must measure what matters. Data, not feelings, should guide your decisions. This data-driven approach is the core of successful Virtual clothing quality assurance for American buyers.

Your core KPIs should include:

- Defects per Hundred Units (DHU): The average number of defects found per 100 units inspected.

- First Pass Yield (FPY): The percentage of products that pass inspection the first time without needing rework.

- Rework Rate: The percentage of products that require rework.

- On-time Final Approval: The percentage of orders approved on schedule.

You also need clear SLAs for communication. We recommend a tiered approach:

- Level 1 (Minor Issue): Preliminary report within 24 hours.

- Level 2 (Major Issue): RCA report within 48–72 hours.

- Level 3 (Critical Issue): CPAR implemented within 3–5 business days.

The Return on Investment (ROI) is clear. A good system for Remote Clothing Quality Control for US Buyers in Vietnam can reduce DHU by 20–40%. It can eliminate 1–2 expensive trips per quarter. For a 20,000-unit order, a 30% DHU reduction can save thousands in rework costs. This is the tangible value of a professional Remote garment quality inspection for US importers. These savings demonstrate how a strong program for Virtual clothing quality assurance for American buyers quickly pays for itself.

Risks and mitigations

There are common challenges in remote QC. Here is how to prevent them with a proactive plan. A good system for Remote Clothing Quality Control for US Buyers anticipates these problems.

- Risk: The factory misunderstands a specification due to a language barrier or vague instructions.

- Mitigation: Use highly visual tech packs. Include photos and short videos that show exactly how to measure each POM.

- Risk: Time zone delays slow down critical decisions and approvals.

- Mitigation: Schedule a fixed weekly meeting time for status updates. Establish a clear escalation channel (e.g., WhatsApp) for urgent issues.

- Risk: Poor photo or video quality makes it hard to judge quality accurately.

- Mitigation: Provide your partner with a checklist for camera settings. Include standards for lighting conditions and required photo angles.

- Risk: The factory uses an old, outdated version of your tech pack.

- Mitigation: Implement a mandatory change log. Require a digital sign-off from the factory manager for each new version of the tech pack.

Frequently Asked Questions (FAQ)

Q1: What AQL level is suitable for knit t-shirts?

A common starting point for knit products is a Major 2.5 and Minor 4.0 standard. However, this should be adjusted based on your brand’s specific risk profile and customer expectations. A premium brand may choose a stricter level.

Q2: Can remote QC completely replace on-site visits?

Not always. The best approach is a hybrid model. The level of on-site presence should be based on the risk level of the supplier and the technical complexity of the style. Remote QC works best when supported by a trusted local partner.

Q3: Is AI accurate enough for apparel QC?

AI is an excellent tool to assist and support human inspectors. It can flag potential points of interest for review. However, the final quality decision should always be made by a skilled and experienced QC professional.

Q4: Which checklist should I start with?

Start with the inline inspection checklist for a single product style. This allows you to pilot the process and refine your standards before scaling. You can download our template to begin.

Aligning with search intent and next steps

This guide provides a comprehensive framework for Remote garment quality inspection for US importers. It moves beyond simple checklists. It offers a true system for proactive quality management. After reading this, you have the tools to implement a professional program for Virtual clothing quality assurance for American buyers. You have a 3-layer framework. You have a downloadable checklist. You have sample KPIs and a case study with real-world data. This is your roadmap to achieving consistent quality and peace of mind. Your next step is to put this knowledge into action. A demonstration is the best way to see how this applies to your products.

Your 30–60–90 day rollout plan

You can roll this out in manageable stages. This makes implementing Remote Clothing Quality Control for US Buyers in Vietnam an achievable goal.

- Days 0–30: Foundation.

Standardize your tech packs to be “Ready-for-QC.” Pilot the inline inspection process on one or two core styles. Create your checklist and video measurement guides. This foundational work is the first practical step in your system for Remote Clothing Quality Control for US Buyers in Vietnam. - Days 31–60: Scaling.

Expand the final AQL process to more of your product line. Build your KPI dashboard in a simple tool like Google Sheets. This dashboard provides the data to manage your Remote Clothing Quality Control for US Buyers in Vietnam effectively. You can also begin to experiment with AI-assisted tools on a small scale. - Days 61–90: Optimization.

Standardize your RCA and CPAR process across all suppliers. Create a formal Standard Operating Procedure (SOP). This SOP defines your official, repeatable process for Remote Clothing Quality Control for US Buyers in Vietnam. Finally, evaluate your 90-day ROI to make a data-driven decision to scale up the program.

The role of a Vietnam-based QC partner

A partner in Vietnam acts as your “extended arm.” They are your eyes and ears on the factory floor. They can quickly validate issues. This prevents small problems from becoming large disasters. They serve as your objective representative in quality discussions with the factory. Most importantly, they can supervise the CPAR process on-site. This ensures that corrective actions are actually implemented and sustained over time. They bridge the critical gap between your remote management and the on-site reality. This partnership is the ultimate key to successful Remote Clothing Quality Control for US Buyers in Vietnam. It ensures the long-term success of your Virtual clothing quality assurance for American buyers program.

Conclusion and your next step

Effective Remote Clothing Quality Control for US Buyers in Vietnam is not only possible; it is the new standard. It is essential for efficient and resilient supply chains. Success requires a proactive system. It begins with a perfect tech pack. It is supported by a reliable CPAR process. It also requires a trusted presence on the ground. This combination of a robust system and a local partner is what delivers consistent quality. It provides on-time delivery and true peace of mind. The modern approach to Remote garment quality inspection for US importers is your competitive advantage.

See how this framework can be applied to your products. Schedule a complimentary 15-minute demo. We will use your own tech pack to build and simulate a virtual QC checklist.

About iGreen Tex Vietnam

iGreen Tex Vietnam is a trusted fashion and textile manufacturer based in Vietnam, specializing in high-quality sportswear and casual apparel for global markets. We provide OEM manufacturing services, supporting brands to design, develop, and produce customized garments that meet international quality standards.

Our production focuses on sustainability and eco-friendly practices, using certified fabrics and advanced techniques to reduce environmental impact. From material sourcing to final inspection, every stage of manufacturing follows strict quality control processes to ensure flawless results. With years of experience in Vietnam sportswear manufacturing, we understand the demands of global clients and changing fashion trends.

Our factory operates with modern equipment and a dedicated team to deliver products on time and at competitive pricing. Partnering with iGreen Tex means working with a reliable supplier who combines innovation, quality, and responsibility. We help your brand scale effectively by producing garments that resonate with today’s conscious consumers worldwide.

If you want to read more information about canvas bags, and if you want to tote bags at Ho Chi Minh City, you can see it here!!!

To view product information click here

Visit our website to learn more about our products and services: IGREEN TEX

IGREEN TEX VIETNAM CO LTD

Address: No. 6 – 6A, D52 Street, Bay Hien Ward, Ho Chi Minh City, Vietnam

E-mail: Info@iGreentex.com

WhatsApp/Viber/Zalo: +84 (0) 938.045.900