Starting a fashion brand involves more than just creative designs; it requires making strategic decisions about production. Choosing the right manufacturing option can directly impact your product quality, scalability, and brand identity. This blog explores the most popular production methods for fashion startups and helps you determine the optimal choice for your business.

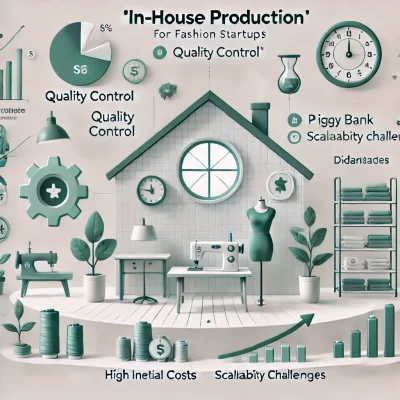

In-House Production

In-house production involves managing the entire manufacturing process within your own company.

Advantages:

- Quality Control: Oversee every step to ensure products meet your standards.

- Flexibility: Easily adjust designs and schedules to meet demands.

Disadvantages:

- High Initial Costs: Significant investment in machinery, staff, and space.

- Scalability Challenges: Expanding production as your business grows can be costly and complex.

Domestic Manufacturing

This option involves partnering with manufacturers in your country.

Advantages:

- Ease of Communication: Fewer language and cultural barriers make collaboration smoother.

- Faster Shipping: Proximity reduces delivery time.

Disadvantages:

- Higher Costs: Domestic production is often more expensive, especially in developed countries.

- Limited Materials: Access to specialty fabrics or materials may be restricted locally.

For insights into the benefits of domestic production with sustainable practices, check out iGreen Tex’s post:

“The Importance of Choosing Sustainable Manufacturers”

International Manufacturing

International manufacturing offers cost savings and large-scale production capabilities.

Advantages:

- Lower Costs: Benefit from lower labor and material costs.

- High Capacity: Ideal for producing in bulk.

Disadvantages:

- Quality Control Risks: Distance makes supervision challenging.

- Longer Lead Times: Shipping from overseas can take weeks or months.

If you’re considering international production, ensure your partner has rigorous quality assurance processes. Learn about how iGreen Tex maintains quality in global manufacturing:

“How We Ensure Quality in Every Garment at iGreen Tex”

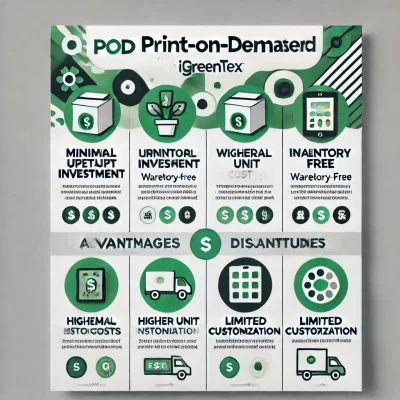

Print-On-Demand (POD)

POD is a low-risk model where products are only manufactured after they’re sold.

Advantages:

- Minimal Upfront Investment: No need to produce large quantities before selling.

- Inventory-Free: Avoid overproduction and waste.

Disadvantages:

- Higher Unit Costs: Individual production costs are higher than bulk manufacturing.

- Limited Customization: Options for material and design adjustments are often restricted.

Choosing the Right Manufacturing Partner

Selecting the right production partner goes beyond cost considerations. Factors like sustainability, quality, and alignment with your brand’s values are equally critical.

Why Choose iGreen Tex?

- Sustainable Materials: We offer eco-friendly fabrics such as organic cotton, recycled textiles, and biodegradable polyester.

- Comprehensive Services: From design to production, we handle it all under one roof.

- Strict Quality Checks: Every product undergoes thorough inspections to meet premium standards.

- Startup Support: Flexible solutions tailored for emerging brands.

Explore our post on sustainability:

“Sourcing Premium and Sustainable Materials”

Conclusion

Each production option has its pros and cons. The key is to assess your needs, budget, and brand goals before deciding.

If you’re looking for a reliable, sustainable, and experienced production partner, contact iGreen Tex today for personalized solutions that fit your business.

About IGREEN TEX

IGREEN TEX is a provider of fashion and textile products, offering a wide range of apparel both domestically and internationally. Our commitment to quality ensures that our products not only meet the highest standards but also promote eco-friendly practices.

IGREEN TEX VIETNAM CO LTD

Address: No. 83, A4 Street, Ward 12, Tan Binh Dist, HCMC

Tax code: 0315844409

Email: info@igreentex.com

WhatsApp/Viber/Zalo: +84 938.045.900