- From Green Vision to Quality Products: A Comprehensive Guide to Choosing Sustainable Fabrics for Apparel Brands

- Understanding the Sustainable Fabric Revolution

- Essential Sustainable Fabric Categories

- Strategic Evaluation Framework

- Certification and Verification Systems

- Practical Selection Process

- Integration with Manufacturing Partners

- Marketing and Consumer Communication

- Risk Management and Mitigation

- Future Trends and Opportunities

- Measuring Success and Continuous Improvement

- Conclusion

- About IGREEN TEX

- IGREEN TEX VIETNAM CO LTD

From Green Vision to Quality Products: A Comprehensive Guide to Choosing Sustainable Fabrics for Apparel Brands

The fashion industry faces unprecedented pressure to adopt sustainable practices. Consumer demand for eco-friendly products continues growing across all market segments. Yet many brand owners struggle with the complexity of choosing sustainable fabrics for apparel brands.

This comprehensive guide transforms confusion into clarity. We provide practical tools to navigate the sustainable fabric landscape effectively. Modern businesses need strategic approaches that balance environmental responsibility with commercial success.

Choosing sustainable fabrics for apparel brands requires more than good intentions. It demands technical knowledge, systematic evaluation, and strategic partnerships. This guide helps brands make informed decisions that benefit both business performance and environmental goals.

See more: Vietnam Apparel Production Scalability for Streetwear Brand

See more: Ethical Streetwear Production Vietnam

See more: Vietnam’s Textile Innovation Hubs for Streetwear Development

See more: Risk Mitigation Strategies for Manufacturing Streetwear

See more: Quality Assurance Benchmarks for Vietnamese-Made Streetwear

See more: How to Build Partnerships Vietnamese Apparel Factories

Understanding the Sustainable Fabric Revolution

The sustainable fabric market has evolved dramatically over the past decade. Today’s brands face numerous eco-friendly options ranging from organic cotton to bio-based innovations. However, choosing sustainable fabrics for apparel brands involves complex considerations beyond environmental impact.

Sustainable fabrics represent materials produced with minimal environmental footprint throughout their lifecycle. This includes fiber cultivation, manufacturing processes, dyeing techniques, and end-of-life disposal. The challenge lies in understanding that sustainability encompasses multiple dimensions.

Environmental impact forms just one aspect of sustainable fabric selection. Social responsibility, economic viability, and performance requirements all influence decision-making. Choosing sustainable fabrics for apparel brands requires balancing these competing priorities effectively.

Modern supply chains add complexity to sustainable fabric selection. Global sourcing, quality standards, and cost pressures create challenging trade-offs. Brands must navigate these complexities while maintaining product quality and market competitiveness.

Essential Sustainable Fabric Categories

Organic Cotton: The Foundation Option

Organic cotton remains the most widely recognized sustainable fabric choice. Grown without synthetic pesticides or fertilizers, it offers familiar properties that designers understand. Organic cotton works exceptionally well for basic apparel items including t-shirts and casual wear.

The main advantages include breathability, softness, and proven durability. However, organic cotton requires significantly more water during cultivation than conventional alternatives. Brands must consider this trade-off when choosing sustainable fabrics for apparel brands focused on water conservation.

Cost premiums for organic cotton typically range from 15-25% above conventional cotton. Supply chain availability has improved significantly, making organic cotton accessible for most brands. Quality consistency matches conventional cotton when sourced from experienced suppliers.

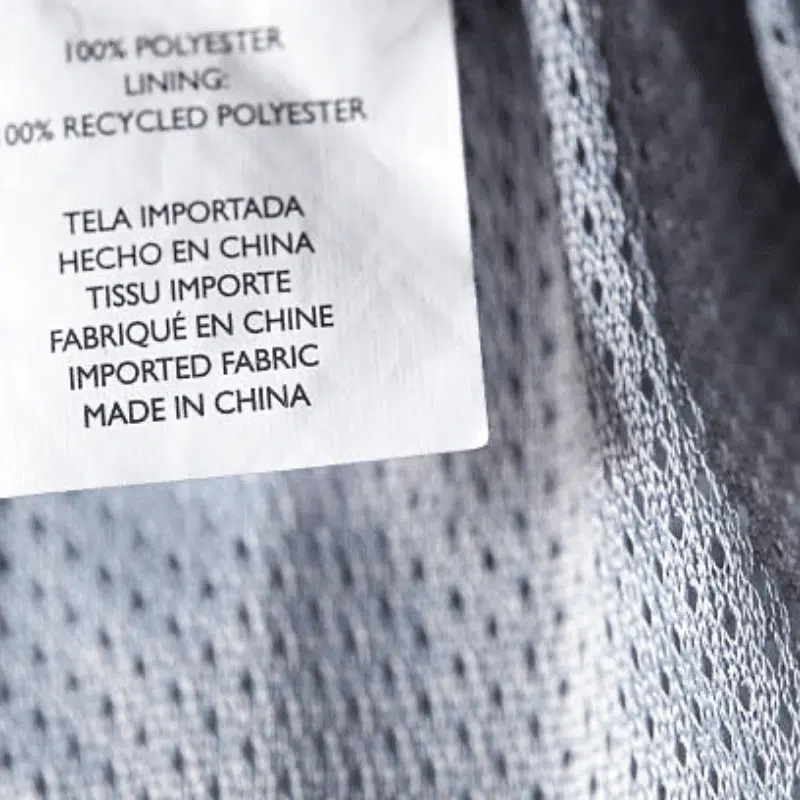

Recycled Polyester: Performance with Purpose

Recycled polyester transforms plastic waste into functional fabric options. This material appeals to brands seeking performance characteristics while reducing environmental impact. Recycled polyester offers excellent moisture-wicking properties ideal for activewear applications.

The recycling process requires 59% less energy than producing virgin polyester. However, synthetic fabrics still shed microplastics during washing cycles. Brands must consider this factor when choosing sustainable fabrics for apparel brands targeting environmentally conscious consumers.

Cost parity with virgin polyester makes recycled options financially attractive. Supply availability continues improving as recycling infrastructure expands globally. Quality performance matches virgin polyester when sourced from reputable manufacturers.

Tencel and Lyocell: Versatile Innovation

Tencel and lyocell fabrics derive from sustainably sourced wood pulp. These materials offer silk-like properties with enhanced breathability and moisture management. The closed-loop production process recycles water and solvents, minimizing waste generation.

These fabrics work exceptionally well for both casual and formal wear applications. They provide natural antimicrobial properties and excellent draping characteristics. However, sourcing transparency remains crucial when choosing sustainable fabrics for apparel brands committed to responsible forestry.

Premium pricing typically ranges 20-40% above conventional alternatives. Supply chain reliability has improved significantly with major manufacturers expanding production capacity. Quality consistency meets high-end fashion requirements when properly sourced.

Hemp: Durability and Sustainability

Hemp fabric offers exceptional durability while requiring minimal water for cultivation. It grows quickly without pesticides and actually improves soil health. Hemp becomes softer with washing while maintaining structural integrity.

This fabric suits brands focusing on longevity and durability messaging. However, hemp’s initial texture may feel rough compared to conventional fabrics. Blending hemp with other fibers often provides optimal results when choosing sustainable fabrics for apparel brands.

Cost premiums range from 25-35% above conventional alternatives. Supply availability remains limited but continues expanding. Quality improvements have made hemp more appealing for mainstream fashion applications.

Bamboo Fabric: Fast-Growing Promise

Bamboo grows rapidly and requires minimal cultivation resources. However, conversion from bamboo plant to fabric varies significantly in sustainability impact. Mechanical processing creates truly sustainable bamboo fabric options.

Chemical processing may involve harsh chemicals that compromise sustainability benefits. Brands must verify production methods when choosing sustainable fabrics for apparel brands committed to authentic sustainability. Properly processed bamboo offers excellent moisture-wicking and antimicrobial properties.

Cost competitiveness varies based on processing method and quality standards. Supply chain transparency requires careful supplier evaluation. Quality consistency depends heavily on manufacturing expertise and process control.

Strategic Evaluation Framework

Environmental Impact Assessment

Comprehensive environmental assessment forms the foundation of sustainable fabric selection. This evaluation includes water usage, chemical inputs, energy consumption, and waste generation. Choosing sustainable fabrics for apparel brands requires understanding these impacts throughout the supply chain.

Life cycle assessment tools help quantify environmental impacts objectively. Consider fiber source, processing methods, and transportation distances. Local sourcing often reduces environmental impact while supporting regional economies.

Carbon footprint calculations provide valuable comparison data between fabric options. Water usage metrics help identify fabrics aligned with conservation goals. Waste generation analysis reveals opportunities for circular economy integration.

Performance and Quality Requirements

Sustainable fabrics must meet performance standards for their intended applications. Athletic wear requires moisture-wicking properties while formal wear needs drape and appearance retention. Testing fabric samples under real-world conditions prevents costly mistakes.

Durability directly impacts sustainability through extended product lifecycles. Fabrics maintaining quality through multiple wash cycles reduce overall environmental impact. Consider pilling resistance, color fastness, and dimensional stability when choosing sustainable fabrics for apparel brands.

Performance testing should include wash durability, color retention, and structural integrity. Comparison testing against conventional alternatives provides objective quality metrics. Independent testing laboratories offer credible verification of performance claims.

Cost Analysis and Financial Planning

Sustainable fabrics often command premium prices compared to conventional options. However, total cost of ownership includes durability, brand value, and consumer willingness to pay. Choosing sustainable fabrics for apparel brands requires balancing initial costs with long-term benefits.

Volume purchasing agreements can reduce per-unit costs significantly. Long-term contracts provide price stability and supply security. Premium pricing opportunities often offset higher material costs for brands with strong sustainability positioning.

Financial modeling should include material costs, processing premiums, and potential price increases. Market research helps validate consumer willingness to pay premiums. Competitive analysis reveals pricing strategies used by successful sustainable brands.

Supply Chain Reliability

Supply chain reliability affects production scheduling and inventory management. Establish relationships with suppliers providing consistent quality and delivery timelines. Consider minimum order quantities and lead times when choosing sustainable fabrics for apparel brands.

Supplier financial stability impacts long-term relationship viability. Multiple supplier relationships reduce dependency risks. Geographic diversification protects against regional supply disruptions.

Supplier auditing ensures compliance with sustainability standards. Regular quality assessments maintain consistent material standards. Clear communication protocols prevent misunderstandings and delivery issues.

When sourcing materials for your brand, especially for distinctive lines like kate ford clothing, selecting the right fabric is paramount. Understanding the nuances of different materials will ensure your garments meet quality expectations and aesthetic goals. Discover more about the options available by exploring the 6 Types of Kate Fabric Commonly Used Today

To bring your kate ford clothing designs to life, partnering with a reliable manufacturer is crucial. Gain insight into our capabilities and dedication at Our Garment Factory in Ho Chi Minh. Additionally, understanding market dynamics helps in budgeting, so review the Apparel Manufacturing Costs in Vietnam for brands targeting US and UK markets.

Making informed choices about both fabric and production partners is key to the success of any kate ford clothing collection. To ensure you collaborate with top-tier providers, consult our comprehensive guide on Finding the Best Clothing Manufacturers We are committed to helping you achieve excellence in your apparel production.

Certification and Verification Systems

Understanding Key Certifications

Multiple certification systems verify sustainable fabric claims with varying levels of rigor. The Global Organic Textile Standard (GOTS) ensures organic fiber content and environmental criteria. The Organic Content Standard (OCS) verifies organic fiber content without additional requirements.

The Global Recycled Standard (GRS) validates recycled content and social practices. The bluesign system ensures chemical safety throughout the textile value chain. Understanding these certifications helps when choosing sustainable fabrics for apparel brands.

Certification costs vary significantly based on scope and requirements. Some certifications focus solely on fiber content while others encompass entire supply chains. Choose certifications aligned with brand values and consumer expectations.

Evaluating Certification Credibility

Not all certifications offer equal rigor or market credibility. Research certification bodies and their standards before making decisions. Third-party verification provides more credibility than self-certification claims.

Consider the audit frequency and enforcement mechanisms of each certification. Some programs require annual audits while others rely on periodic reviews. Strong enforcement mechanisms ensure continued compliance when choosing sustainable fabrics for apparel brands.

Market recognition affects the marketing value of different certifications. Consumer awareness varies significantly between certification programs. Choose certifications that resonate with target market segments.

Working with Certified Suppliers

Establish relationships with suppliers maintaining multiple relevant certifications. This provides flexibility while ensuring consistent quality standards. Certified suppliers often offer better transparency and traceability than conventional alternatives.

Request documentation and audit reports from potential suppliers. Verify certification validity and renewal dates. Maintain records for marketing claims and regulatory compliance when choosing sustainable fabrics for apparel brands.

Collaborative relationships with certified suppliers enable custom development projects. Shared sustainability goals create stronger partnerships. Regular communication ensures alignment on quality and delivery expectations.

Practical Selection Process

Step 1: Requirements Definition

Begin by clearly defining product requirements including performance needs, aesthetic goals, and budget constraints. Document these requirements to guide fabric evaluation and selection decisions. Consider creating weighted scoring systems for objective evaluation.

Identify non-negotiable criteria versus desirable features. This helps prioritize options when perfect solutions don’t exist. Market research provides insights into consumer expectations and willingness to pay premiums.

Technical specifications should include performance requirements, quality standards, and sustainability criteria. Clear requirements enable effective supplier communication when choosing sustainable fabrics for apparel brands.

Step 2: Market Research and Shortlisting

Research available sustainable fabric options meeting basic requirements. Create shortlists of three to five options for detailed evaluation. Consider both fiber types and supplier capabilities during initial screening.

Gather technical specifications, certifications, and pricing information for each option. Request samples for physical evaluation and testing. Document all information systematically for comparison purposes.

Industry reports provide market intelligence on emerging sustainable fabric options. Trade shows offer opportunities to evaluate new materials directly. Supplier presentations provide detailed technical information when choosing sustainable fabrics for apparel brands.

Step 3: Testing and Evaluation

Conduct thorough testing of shortlisted fabrics including appearance, hand feel, drape, and performance characteristics. Consider both initial properties and behavior after washing and wear. Independent testing provides objective comparison data.

Involve key stakeholders in evaluation processes including designers, production managers, and quality control personnel. Each perspective offers valuable insights. Document feedback systematically for decision-making purposes.

Prototype development reveals potential issues before large-scale production. Small production runs identify processing challenges. Consumer testing provides market feedback when choosing sustainable fabrics for apparel brands.

Step 4: Supplier Assessment

Evaluate potential suppliers beyond fabric quality including production capacity, quality systems, and sustainability practices. Transparent sustainable supply chain for global streetwear brands vietnam requires careful supplier selection and ongoing relationship management.

Visit supplier facilities when possible to assess working conditions, environmental practices, and quality control systems. Build relationships with suppliers sharing brand values and sustainability commitments.

Financial assessment ensures supplier stability and long-term viability. Reference checks provide insights into supplier reliability and performance. Clear agreements protect both parties when choosing sustainable fabrics for apparel brands.

Step 5: Decision Making and Implementation

Compile evaluation data to make informed decisions considering both quantitative metrics and qualitative factors. Document decision rationale for future reference and continuous improvement efforts.

Implementation planning addresses production requirements, quality control procedures, and marketing strategies. Staff training ensures proper handling of new materials. Monitoring systems track performance against expectations.

Continuous improvement processes incorporate learning from initial implementations. Regular reviews identify optimization opportunities. Market feedback guides future decisions when choosing sustainable fabrics for apparel brands.

Integration with Manufacturing Partners

Selecting Experienced Partners

Choose manufacturing partners with experience in sustainable fabric processing. Companies like iGreen Tex Vietnam specialize in sustainable textile production and understand unique requirements. Experienced partners provide valuable guidance throughout the selection process.

Manufacturing expertise complements design vision and market knowledge. Collaborative development approaches often yield better outcomes than working independently. Shared sustainability goals create stronger partnerships.

Quality assurance capabilities ensure consistent results throughout production runs. Established quality systems reduce risks associated with new materials. Technical support helps optimize processing parameters when choosing sustainable fabrics for apparel brands.

Collaborative Development

Work collaboratively with manufacturing partners during fabric selection and development processes. Their technical expertise identifies potential issues early. Regular communication ensures alignment on requirements and expectations.

Joint development projects create custom solutions meeting specific brand requirements. Shared investment in development creates stronger partnerships. Intellectual property agreements protect innovations when choosing sustainable fabrics for apparel brands.

Knowledge sharing accelerates learning and improvement processes. Best practice documentation supports scalability. Continuous improvement processes benefit all parties involved.

Production Optimization

Sustainable fabrics may require different handling procedures during production processes. Train production staff on proper techniques for each fabric type. Water conservation techniques in textile industry vietnam help optimize processing efficiency.

Adjust quality control procedures to account for sustainable fabric characteristics. Some materials may have different appearance standards or performance expectations. Process optimization reduces waste and improves efficiency.

Capacity planning ensures adequate production capability for sustainable fabric programs. Equipment modifications may be necessary for optimal results. Investment planning supports long-term sustainability goals when choosing sustainable fabrics for apparel brands.

Marketing and Consumer Communication

Authentic Storytelling

Marketing sustainable fashion to conscious consumers requires authentic storytelling about fabric choices and sustainability commitments. Develop messaging explaining benefits and trade-offs of sustainable fabric selection. Educational content builds consumer understanding and loyalty.

Transparency in communication builds trust with environmentally conscious consumers. Share information about challenges and improvements in sustainable fabric adoption. Authentic messaging resonates more strongly than generic sustainability claims.

Visual storytelling helps communicate complex sustainability concepts effectively. Behind-the-scenes content showcases sustainable production processes. Consumer education materials support informed purchasing decisions when choosing sustainable fabrics for apparel brands.

Brand Positioning and Differentiation

Sustainable fabric choices enable unique brand positioning in competitive markets. Authentic sustainability credentials differentiate from competitors making superficial claims. Clear positioning attracts target consumers willing to pay premiums.

Competitive analysis reveals positioning opportunities and market gaps. Unique value propositions justify premium pricing. Brand consistency across all communications reinforces positioning when choosing sustainable fabrics for apparel brands.

Partnership messaging with suppliers like iGreen Tex Vietnam demonstrates supply chain commitment. Third-party endorsements provide credibility. Industry recognition supports brand positioning efforts.

Consumer Education and Engagement

Educational content helps consumers understand sustainable fabric benefits and proper care instructions. Informed consumers make better purchasing decisions and maintain products longer. Engagement strategies build community around sustainability values.

Care instruction optimization extends product lifecycles and maintains fabric performance. Proper washing techniques preserve fabric properties. Consumer education reduces returns and increases satisfaction when choosing sustainable fabrics for apparel brands.

Feedback collection provides insights into consumer preferences and market trends. Regular surveys track brand perception and satisfaction. Social media engagement builds community and brand loyalty.

Risk Management and Mitigation

Supply Chain Risks

Sustainable fabric supply chains may face different risks than conventional alternatives. Limited supplier bases create dependency risks. Geographic concentration increases vulnerability to disruptions.

Diversification strategies reduce dependency on single suppliers or regions. Multiple supplier relationships provide backup options. Long-term contracts balance security with flexibility when choosing sustainable fabrics for apparel brands.

Risk assessment frameworks identify potential issues before they impact operations. Contingency planning ensures business continuity. Insurance coverage protects against supply chain disruptions.

Quality and Performance Risks

New sustainable fabrics may present unfamiliar quality or performance challenges. Thorough testing reduces these risks but cannot eliminate them entirely. Quality assurance systems must adapt to new materials.

Supplier qualification processes ensure consistent quality standards. Regular quality audits maintain performance levels. Performance guarantees protect against material failures when choosing sustainable fabrics for apparel brands.

Consumer expectations management prevents disappointment with different fabric properties. Clear communication about characteristics and limitations builds realistic expectations. Return policies accommodate learning phases.

Financial and Market Risks

Premium pricing for sustainable fabrics creates financial risks if market demand weakens. Cost volatility affects profitability and pricing strategies. Market acceptance may vary by region and consumer segment.

Financial modeling scenarios evaluate different market conditions. Flexible pricing strategies adapt to changing conditions. Diversified product portfolios balance risk exposure when choosing sustainable fabrics for apparel brands.

Market research tracks consumer preferences and willingness to pay. Competitive monitoring reveals market trends and opportunities. Financial reserves support investment in sustainable fabric programs.

Future Trends and Opportunities

Emerging Technologies

Innovation continues driving sustainable fabric development with new technologies creating options from agricultural waste, algae, and other sources. Early adoption of breakthrough technologies provides competitive advantages.

Biotechnology applications create new fiber sources and processing methods. Nanotechnology improves fabric performance while maintaining sustainability benefits. Digital integration optimizes supply chain efficiency when choosing sustainable fabrics for apparel brands.

Investment in research and development supports long-term competitiveness. Partnerships with technology developers provide early access to innovations. Pilot programs test new materials before large-scale adoption.

Circular Economy Integration

Future sustainable fabric strategies increasingly focus on circular economy principles. This includes designing for recyclability, developing take-back programs, and creating closed-loop material flows.

End-of-life planning during fabric selection supports circular economy goals. Recycling capabilities influence material choices. Consumer education promotes proper disposal and recycling when choosing sustainable fabrics for apparel brands.

Partnership development with recycling companies creates circular systems. Investment in recycling infrastructure supports long-term sustainability. Policy advocacy promotes circular economy development.

Market Evolution

Consumer awareness and demand for sustainable products continue growing across all market segments. Regulatory requirements increasingly favor sustainable practices. Market leaders establish standards for industry transformation.

Competitive dynamics shift as sustainability becomes mainstream. Early adopters maintain advantages through experience and established relationships. Market consolidation creates opportunities for differentiation when choosing sustainable fabrics for apparel brands.

Global expansion of sustainable fabric markets creates new opportunities. Regional preferences influence fabric selection strategies. Overcoming challenges in implementing ethical apparel production requires adapting to diverse market conditions.

Measuring Success and Continuous Improvement

Key Performance Indicators

Establish clear metrics for measuring sustainable fabric program success. Environmental impact reductions, quality improvements, and cost performance provide objective measures. Consumer satisfaction and brand perception track market response.

Regular monitoring ensures programs remain effective and aligned with objectives. Benchmark comparisons reveal relative performance. Trend analysis identifies improvement opportunities when choosing sustainable fabrics for apparel brands.

Reporting systems track progress against established goals. Dashboard presentations summarize key metrics for management review. Stakeholder communication demonstrates program value.

Continuous Improvement Processes

Learning from implementation experiences guides future decisions. Regular program reviews identify optimization opportunities. Best practice documentation supports scalability and knowledge sharing.

Feedback incorporation improves program effectiveness over time. Market research updates understanding of consumer preferences. Supplier feedback provides operational insights when choosing sustainable fabrics for apparel brands.

Innovation integration keeps programs current with market developments. Technology adoption improves efficiency and effectiveness. Partnership development creates new opportunities for improvement.

Conclusion

Choosing sustainable fabrics for apparel brands represents both challenge and opportunity for modern fashion businesses. Success requires systematic approaches balancing environmental goals with commercial requirements. This comprehensive guide provides frameworks for making informed decisions.

Strategic partnerships with experienced manufacturers like iGreen Tex Vietnam simplify implementation while ensuring quality results. Their expertise helps brands navigate complex decisions when choosing sustainable fabrics for apparel brands.

The future of fashion depends on decisions made today. Brands implementing sustainable fabric strategies build competitive advantages while contributing to industry transformation. The journey toward sustainability begins with informed fabric choices that benefit both business performance and environmental goals.

Through careful planning, systematic evaluation, and strategic partnerships, any brand can successfully integrate sustainable fabrics into their operations. The question is not whether to embrace sustainability, but how quickly and effectively to implement strategies that create lasting value for all stakeholders.

About IGREEN TEX

IGREEN TEX is a provider of fashion and textile products, offering a wide range of both domestically and internationally. Our commitment to quality ensures that our products not only meet the highest standards but also promote eco-friendly practices, in Vietnam sportswear manufacturing.

If you want to read more information about canvas bags, and if you want to tote bags at Tphcm, you can see it here!!!

To view product information click here

Visit our website to learn more about our products and services: IGREEN TEX

IGREEN TEX VIETNAM CO LTD

Address: No. 6 – 6A, D52 Street, Ward Bay Hien, HCMC

E-mail: info@igreentex.com

WhatsApp/Viber/Zalo: +84 938.045.900